Many founders want crystal-clean vodka, but the destilación hardware and setup feel confusing. Confusion leads to off-notes and wasted runs. Use this guide to build a simple, reliable column configuration that scales and produces a clean, market-ready spirit.

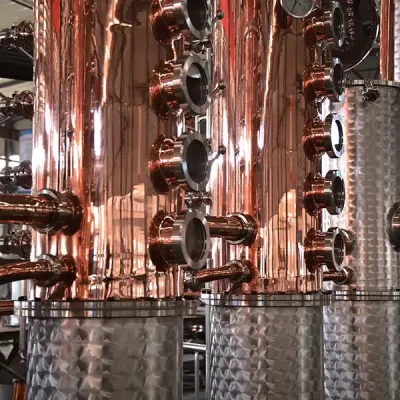

A vodka distillation column setup uses a heated kettle, a reflux columna todavía (with plates or packing), a condenser, and controls for heat and reflux. Wash is fed into the column or boiled in the kettle; rising vapor contacts plates/packing to increase purity (more “theoretical plates”), then condenses to high-abv spirit. For vodka, design for strong reflux, adequate plates, stable cooling, and safe takeoff to a collection vessel. Regulations define neutral spirits at ≥95% ABV (190 proof).

What is a vodka column and how does a column still work?

A vodka column is a tall, vertical columns assembly that increases purity through controlled contact between rising alcohol vapor and descending liquid. The heart of this proceso de destilación is equilibrium: vapor rises, cools, and condense; liquid flows back down the column; each contact zone acts like a “theoretical plates,” boosting purity step by step.

A columna todavía is favored because it delivers high purity at steady throughput. In simple terms, here’s how a column still works: a heated pava boils the fermented wash; vapor climbs and repeatedly contacts packing or trays; lighter compounds move upward to the top of the column, heavier ones fall column due to gravity; the cleanest destilado is drawn near the top, routed to a condenser, and cooled back into liquid.

“More contact stages (plates/packing) = higher purity.” That’s the core idea behind column distillation, and it’s why vodka columns are taller or more efficient than many columns used to distill flavorful spirits.

Pot still vs column still for vodka: what’s the difference?

Alambique setups shine when you want character. Classic pot distillation (often in a copper pot) carries more congeners—great for pot still whiskey, malt whiskyo brandy—but less ideal for neutral vodka. Traditional pot-still runs also generate low wines that usually need additional distillations.

A columna todavía is engineered to distill to a much higher percentage of alcohol in fewer steps. It can produce neutral alcohol efficient enough for the production of vodka, while a pot is the type of still you choose for whisky, rum, ginebra, scotcho grain whisky styles that keep a flavor profile. In short: pot = flavor; column = clean.

If you ever want to diversify, a modular column can be run at lower reflux for vodka and gin experiments with light botanical notes or an infused vodka line. That flexibility helps a small team deliver a consistent product without buying a second line.

Compare footprints and utilities in alcohol distillation equipment.

Continuous distillation vs batch: which suits a startup?

Many craft operations start with lote runs (heat, take off, reset)—easy to learn and flexible. A well-designed batch distillation flow in a single column can meet early demand and keep capital light.

Larger plants adopt continuous distillation with a continuous column, sometimes the modern descendant of the Coffey still: feed in one side, product out the other, steady all day. It’s brilliant for volume, but it’s more complex to commission and automate.

For tight budgets, shortlist affordable distillery equipment that still scales.

Choosing feedstock, mash, and yeast: start clean to finish clean

For neutral spirits, start with clean, fermentable feedstock. Vodka is often made from grains (corn, wheat, rye), but you’ll also see potatoes or sugar beets. If you’re targeting absolute neutrality, smooth starch conversion and a clean puré help a lot. Mention grain choices clearly—barley o malted barley blends can be used, though you’ll keep malt contributions subtle.

Keep your fermentations tidy. You only need to fermentar once, but keep it cool and consistent. The type of yeast used shapes by-products; for vodka, choose low-ester strains that minimize congeners, helping you avoid a sour taste after distilling.

Inside the column: plated column vs packed column

Two common internals:

- Plated column: Discrete plates or traysthat create contact stages. Easy to visualize cuts; fantastic for teaching teams how each stage affects purity.

- Packed column: A dense packed section(mesh, rings, or structured packing) that offers many contact points in a compact height. A “packed column” is efficient and common in vodka.

Both approaches aim to maximize theoretical plates and let you tune reflux. Tall, straight columns with good dephlegmator control excel for neutral spirits because they efficiently strip heavier compounds.

Reflux, ABV, and the ethanol–water azeotrope

To make good vodka, you need high ABV and minimal congeners. But physics imposes a ceiling: ethanol and water form an azeotrope near 95–96% ABV (about 191–192 proof), which you cannot surpass by simple distilling alone. In U.S. law, “neutral spirits” mean ≥95% percent alcohol by volume.

Quick reference

| Target Purity (est.) | Indicative Plate Count* | Notas |

| 88–90% ABV | ~10–12 | Entry-level neutral for tinctures |

| 92–94% ABV | ~14–18 | Good polishing for blending |

| 95–96% ABV | ~20–30 | Vodka-grade neutrality (U.S. percentage of alcohol rule) |

*Depends on packing, reflux, and heat balance.

ABV vs Plates (illustrative)

Plates: 8 12 16 20 24 28 32

ABV: 86 90 92 94 95 95.5 96

Remember: More reflux = more purity, but slower takeoff. Aim for stable alcohol content at the parrot, not peak flow.

Regulations: “Neutral spirits or alcohol” must be distilled at or above 95% ABV (190° proof). If bottled, at least 40% ABV.

Heads, hearts, tails: managing congeners and fusel oils

Even with a tall column, you’ll manage fractions. Up top, you’ll find early “heads,” where some esters and light volatiles live; the “hearts” are your clean run; “tails” carry fusel oils y otros heavier compounds. A small change in reflux can push a congener either direction.

Signs you’re dragging tails: weighty texture, slight aroma shift, or faint sour taste. Learn the feel of your system so the product is drawn at the right purity and proof. Good notes build consistent product across every lote.

Piping, condenser water, and safe cooling

Hot alcohol vapor leaving the rectifying zone must be knocked down by a condenser using stable cooling water. As vapor molecules vaporizar then meet a cold surface, they turn back into liquid—don’t skimp on surface area. Plan for redundancy, flow control, and proper venting.

Size lines for the flow you expect today—and tomorrow. Check seals and sight glasses daily. Make sure you can sample at the parrot and redirect to a feints tank without spills. Use a second condenser if you’re planning very high reflux rates.

Sizing the distillation system: from pilot to production

For a lean build, a single column with modular segments can carry you far. As demand grows, you may add two columns (analyzer/rectifier) for higher throughput akin to a small Coffey still lineage. Modern distillers also like modular frames (think stilldragon-style) because they can re-stack sections as orders grow.

Example throughput guide (approximate)

| Boiler (L) | Plates / Packing Height | Takeoff (L/h @ 95% ABV) | Uso típico |

| 200 | 14–18 | 3–4 | R&D, startup tasting room |

| 500 | 18–24 | 6–8 | Regional destilería launch line |

| 1000 | 24–30 | 10–14 | Steady wholesale orders |

Plan electrical or steam heat, venting, and floor drains. Right-sizing the sistema de destilación saves energy and helps operators focus on the cut window rather than fighting unstable temperatures.

Plan a complete equipos para destilerías comerciales list for your room layout.

Setup steps: from first distillation to final spirit

- Charge: Transfer clarified wash to the boiler; keep solids low to avoid smearing.

- Heat-up: Bring to boil, stabilize reflux. This is your first distillationpass if you’re starting from scratch; many operations polish first distilled low wines on a second run.

- Stabilize: Hold steady, then start a slow takeoff.

- Heads removal: Light volatiles clear first.

- Hearts collection: When steady, the product is drawna la collection vessel.

- Tails control: Watch temp/ABV drift and divert as soon as the cut is past.

- Proofing: Blend with water to target proof (160 proofto storage for some users; proof down again to bottle).

- Rest and filter: Charcoal or other polishing if your spec calls for it.

- Proof to bottle: Bring your final spiritto label proof, test, and package.

Flow note: Liquids flow back down the column while vapors rise; the most volatile fraction collects near the top of the column. Steady heat, careful reflux, and balanced takeoff make the difference between good vodka and rework.

Regulations and definitions that matter

In the U.S., “Neutral spirits or alcohol” are “distilled from any suitable material at or above 95 percent alcohol by volume (190° proof),” and, if bottled, at least 40% ABV. These rules ensure a neutral base used to produce many products, from vodka to liqueurs.

Historically, the Coffey still ushered in efficient neutrality for grain spirits; today’s columns trace that idea. It enabled scalable neutral bases that brands turn into vodka, ginebra, brandyy rum lines depending on proofing, filtration, and flavoring choices.

Materials, flavors, and your roadmap (even if you love whiskey)

You can make vodka made from almost anything fermentable, but clean starches and careful fermentation reduce congeners from the start. If you love whisky too, remember: a tall column can be run for subtle character or stripped for neutral. A short-plate setup can also explore crossover styles, while columns let you hit neutrality faster than most still distillation pot runs.

If you pivot to flavored vodkas, build a plan for flavor and aroma additions after rectification. Keep records of proof, filtration medium, and dosing so your base spirit stays repeatable and aromatic notes are consistent.

Case study: startup to scale (simple numbers)

- Goal:500 L/day at 95% ABV.

- Hardware:500-L boiler, 20-plate plated column with dephlegmator; shell-and-tube knockdown; good reflux controls.

- Process:Heat, stabilize, small takeoff for heads, hold hearts at target proof. Proof to 40% ABV for bottling.

- Outcome:Stable output, low rework, faster time-to-market.

“With 20–24 stages, you typically land near the ethanol/water ceiling—thanks to the azeotrope—and hit neutral specs without heroic energy use.”

Buying, integrating, and expanding (with helpful internal resources)

If you’re building a greenfield line or upgrading, you’ll likely evaluate turnkey options. These guides help you spec tanks, columns, and filling:

- Add a pilot rig with a compact destilador de alcoholfor recipe trials.

- When you’re ready to package, match throughput with a beer bottling machinethat handles spirits bottle formats too.

- If you also brew, align brewhouse capacity with packaging via equipos de cervecería en ventafor a balanced cellar.

Quick troubleshooting: off-notes, proofs, and throughput

- Off-notes (solventy or tails)

Raise reflux, slow takeoff, or increase plate count. Watch for fuselcarryover and adjust your cut points. - Proof short of spec

Add packing or stages; reduce takeoff rate. Don’t chase speed and accept lower abvif your label requires neutral. - Throughput too low

Increase heat gradually and tune reflux to hold proof. When you max the stack, consider a packed sectionupgrade or a second rectifier.

PREGUNTAS FRECUENTES

How many plates do I need for neutral vodka?

Most small columns hit neutral around 20–30 stages (plates or packing). Efficiency varies with design and reflux; that’s why one 20-plate rig may behave like another’s 24.

Why can’t I distill above ~95–96% ABV?

En ethanol–water azeotrope caps purity for simple distilling. You need dehydration tech (molecular sieves, etc.) to go beyond it, which most vodka makers don’t need.

Do columns eliminate flavor completely?

Columns can be run neutral or with some character. Reflux and plate count decide how much flavor profile survives. Fewer plates and gentle reflux retain more.

Can a column help me make whiskey too?

Yes. Many teams produce clean vodka on high reflux, then drop plates or reflux to keep character for whisky variants. Think flexibility first.

Is a Coffey-style rig overkill for a startup?

Usually yes. Start modular; grow when demand proves out. Larger continuous designs originated with the Coffey still, but they require expertise and steady feed flow.

What about safety basics?

Vent properly, ground tanks, manage heat sources, and keep accurate logs. Never run without coolant; always monitor temperatures and proof.

A short glossary (practical, not academic)

- Analyzer / Rectifier:Two-column layouts that split vaporization and rectification duty.

- Reflux:Returning part of condensed product to the column to increase purity.

- Takeoff / Parrot:Where the spirit leaves the system, measured for proof.

- Feints:Heads/tails saved for reprocessing.

Design notes you can use tomorrow

- Build with spare chiller capacity so summer heat doesn’t stall you.

- Add lots of tri-clamp sample points.

- Keep a small inline filter for polishing; you can scale later.

- Log every run. That history is priceless.

Why partner with a manufacturing plant (our perspective)

Como brewing equipment manufacturing team that also engineers columns, we keep things practical: clean welds, hygienic geometry, stable controls, and support from install to first cases. Whether your vodka is made from grains or potatoes, our goal is reliable uptime and repeatable cuts—not showpiece gear that’s hard to run.

Bonus: How columns connect to other spirits

Even if vodka is your launch product, the same column can help you explore ginebra compounding, or a base spirit for liqueurs. It can also make light, grain-forward spirits that bridge toward whisky styles, or support a clean neutral for RTD lines. Diversity reduces risk.

Historical footnote

The rise of continuous column technology in the 1800s reshaped spirits. Aeneas Coffey’s improvements allowed efficient, high-proof runs that underpin modern neutrality—core to vodka today.

Safety & compliance checklist (keep this handy)

- Proof logs align with label claim.

- Cooling capacity verified at your warmest ambient.

- PRVs and vents inspected weekly.

- Chemical-resistant seals inspected for liquid alcohol

- Fire safety and MSDS posted.

- Label class aligns with CFR for “neutral spirits.”

Key specs at a glance (example targets)

- Rectification stages: 20–30 (plates/packing mix)

- Vapor speed: keep stable and laminar where possible

- Reflux ratio: tune to hold target proof without flooding

- Takeoff: start slow; ramp once stable

- Proofing water: carbon-filtered, oxygen-free

Sources (further reading)

- S. definition of neutral spirits / alcohol(≥95% ABV): Title 27 CFR.

- Azeotropebasics and ethanol limits: LibreTexts & Wikipedia.

- Theoretical platesand column efficiency.

- Coffey stilland continuous columns history.

TL;DR — What to remember

- Aim for 20–30 stages and solid reflux to hit vodka-grade neutrality.

- You’ll max near 95–96% ABV because of the ethanol–water azeotrope.

- Control heat, reflux, and coolant to keep proof steady.

- Design for growth: modular columns now, expansion later.

- Log your cuts; consistency beats speed.

- Use trusted suppliers for columns, utilities, and packaging to keep uptime high.

Note on inclusivity of related spirits: While this guide centers on vodka, many principles help when you later explore grain-based whisky expressions or light rum y brandy projects using the same frame.