Big ambitions, tight space, strict codes. Missteps in brewery design cost time and money. Plan holistically—from hot side to piping—to de-risk installation and deliver beer faster.

Designing and installing a large-scale brewery blends engineering with operations. Size the brewhouse, cellar, and chiller for the target output; map a clean, safe layout; specify sanitary piping with CIP; and integrate automation for consistent beer quality. A phased, turnkey approach—covering system designs, piping design and installation, and equipment installation—shortens time to first pour while leaving headroom for growth. Done well, your brewery setup scales with demand and stays maintainable.

Outline

- Capacity planning for the brewhouse, fermenter mix, and chiller sizing

- What brewery layout best supports a clean, safe brewing process?

- Mash, lauter tun, kettle, whirlpool: choosing a brewhouse for scalable brewing

- Automation and control systems for consistent product quality

- Sanitary piping, valves, and CIP system: hygienic foundations

- Glycol, temperature control, and utilities integration across production facilities

- Packaging system choices and material flow in the beer industry

- Micro brewery design vs. large scale breweries: what changes?

- Building around the existing facility: fabrication, floor drains, and ventilation

- Commission, ramp-up, and minimizing downtime during installation

- Staffing, training, and brewing supplies for reliable brewing operations

- Design consultation to turnkey handover: a practical roadmap

Capacity planning for the brewhouse, fermenter mix, and chiller sizing

When you scale a brouwerij, sizing begins with the hot side and flows to the cellar. Pair an appropriate brouwerij with 4–6× cellar volume so each batch has a home. This keeps the brouwer brewing, reduces downtime, and matches market demand with real output while aligning with clear brewing goals.

Tip: plan a path for future tanks before the concrete is saw-cut.

A simple rule links batch count to annual output: turns per day × brew days × brewhouse volume. Then select each fermentor to balance core beers and seasonals, and right-size the koelmachine dus wort hits target temps quickly. That’s how a commerciële brouwerij aligns cellaring with production targets and the promised level of quality.

We always tie decisions back to utilities—steam, water, power—and brewery floor slope. Plan for future tanks and a modular cellar. This first part of the production process determines how you will scale.

What brewery layout best supports a clean, safe brewing process?

A thoughtful brewery layout separates raw materials, hot side, cold side, packaging, and utilities. Clear layout lines cut cross-traffic and keep the brouwproces clean. Use dedicated pijp racks, trench drains, and hose drops so every piece of equipment has access without chaos. Well-designed ventilation and drains are critical in any size facility.

Floors need slope, curb, and non-slip finishes. Provide sanitair zones with hand-wash stations and color-coded tools. Mark forklift lanes, add ventilation, and place grain handling upwind. These basics increase efficiency and protect brewery staff while holding steady product quality. Drainage load can be significant—industry guidance often cites multiple gallons of wastewater per gallon of beer—so plan for it.

Goed system designs also plan people-flow. QA lab sightlines, staging for vat and pallet movement, and quiet alcoves for controls make the space calmer to work in and easier to clean on-site after every shift. Well-planned layouts reduce slips, trips, and contamination risks.

Mash, lauter tun, kettle, whirlpool: choosing a brewhouse for scalable brewing

Pick a hot side that fits your recipes and quantities of beer. A four-vessel set—mash mixer, klaringskuip, ketel, and whirlpool—maximizes turns per day and offers tighter control over the brewing process. Two- and three-vessel brouwerijen work, but four-vessel lines shine when you need speed.

High-shear hydrators reduce dough balls in the giststarter; low-oxygen transfer protects wort; and steam jackets deliver predictable boils in the ketel. Match platform height to ceiling clearances so bags, grist, and hops move safely. This hot side is designed for brewing beer at scale yet still allows small batch trials.

Specify manifold blocks so a sanitary valve sits at every low point. Include targeted automation—rake motors, pump VFDs, flow meters—to minimize operator fatigue while keeping flexibility for recipe changes.

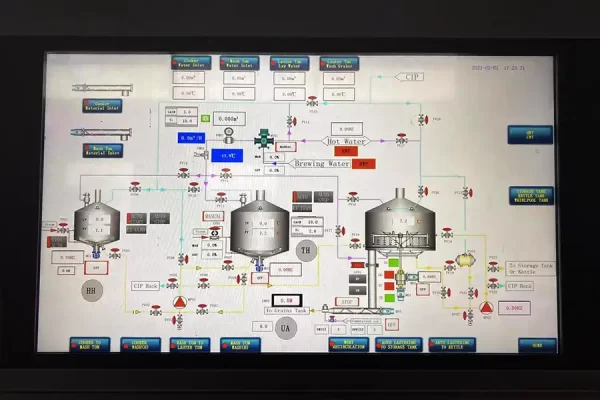

Automation and control systems for consistent product quality

Smart automation locks in consistency. With recipe scheduling, pump interlocks, and alarm logic, your control systems backstop the operator and keep each batch tight. You gain repeatability and efficiency without losing the craft.

Sensors track flow, temperature, and gravity. Data helps the brouwer tune yields and energy use. Combined with trained people, this delivers the product quality customers expect and underpins commercieel brouwen reliability.

Choose platforms that integrate hot side, cellar, and packaging system controls. When every node talks, you move wort faster, chill predictably, and avoid bottlenecks between tanks.

Sanitary piping, valves, and CIP system: hygienic foundations

Hygiene starts with welds and slopes. Specify orbital welds, purge backing, and proper fall on pijp runs. Use a sanitary valve at low points and a ring main for the cip system. A validated cip knocks down soil quickly and safely; it cleans the interiors of pipes, vessels, and tanks without disassembly.

Right fittings matter. Mix-proof ventiel blocks speed changeovers. Sight glasses confirm clarity, and sprayballs clean every tank interior. Documented procedures keep this part of the production process safe for people and beer. Industry seminars and technical bodies provide step-by-step practices worth adopting.

Glycol, temperature control, and utilities integration across production facilities

The cellar lives or dies by temperatuurregeling. Sized headers, insulated drops, and balanced circuits keep glycol flowing to every fermentor and bright tank. A generously sized koelmachine and standby pump protect schedules.

Steam, compressed air, and electrical feeds must match the equipment needed today and tomorrow. Good utility routing supports energy efficiency and safety while keeping aisles clear. Document routes and taps from day one; future additions will be faster and cleaner.

Utilities should be tagged and mapped. When you add vessels, drawings prove you chose the right equipment, not just what was handy.

Packaging system choices and material flow in the beer industry

Your final mile matters. Whether canning, bottling, or draught, the bierindustrie rewards tidy lines and planned buffers. A compact packaging system with date coding and QA checks protects your reputation.

The path from bright tank to pallet should be straight, short, and guarded. Conveyors, rinsers, and palletizers must suit your production needs and be easy to clean. Keep traffic away from open beer and stage materials so the filler never starves.

Even as formats shift, the ambachtelijk bier customer expects consistent fills and clean seams. Protect that standard by embedding QC in the line design and keeping spares on hand for the filler and seamer.

Micro brewery design vs. large scale breweries: what changes?

A microbrouwerij and a regional plant share principles, but scope changes. Bigger vessels, longer runs, and higher utility loads change details—from floor loading to forklift lanes. That’s why micro brewery design rules must expand for scale breweries without losing safety or speed.

Large sites need more automation, more QA, and larger staging zones. They also face additional rules for ventilation and wastewater. Yet the same basics hold: clear separation, cleanable surfaces, and safe traffic patterns.

Regardless of size, the brouwerijsector keeps innovating. The craft beer movement taught us to plan for variety—core lagers, hazy IPAs, and sours—without losing control.

Building around the existing facility: fabrication, floor drains, and ventilation

Many projects happen in an existing facility. Early surveys confirm slab thickness, power capacity, gas service, and vent paths. If needed, add curb, drains, and coatings so wet zones can take abuse. Good fabrication choices—platforms, guards, carts—help you move safely.

Drainage is unsung but vital. Sloped floors, trench sizing, and clean-outs keep work areas dry. Fume hoods and roof vents protect grain handling and boil-off. These details lower slips, improve air, and set a clean baseline. Plan brewery drainage and floors with realistic wastewater rates.

Document every change. A tidy as-built becomes your living map when you add vessels or change a layout later.

Commission, ramp-up, and minimizing downtime during installation

Plan equipment installation in phases: receive, place, anchor, connect, test, and commission. Pre-fabricated skids shorten work and shrink risk on tight timelines.

Dry runs with water, then partial brewing beer trials, flush problems before live production. Treat the first month like an extended FAT: document punch lists, train teams, and protect schedules so downtime stays minimal.

Once the line is stable, lock in SOPs and PMs. You now have a repeatable start-up that safeguards beer production through peaks and maintenance windows.

Staffing, training, and brewing supplies for reliable brewing operations

People make the system sing. Build a core team of operators, a brouwer, maintenance tech, and QA. Stock brewing supplies—gaskets, instruments, cleaning agents—so you can fix small issues fast and keep brewing operations steady.

Create a training ladder. Pair mentors with new hires, document SOPs, and practice changeovers. When people know the why and the how, they protect equipment and beer.

When the team is confident, they use the tools to keep schedules tight and quality high.

Design consultation to turnkey handover: a practical roadmap

A strong project starts with design consultation, moves through engineering, then procurement and fabrication, and ends with bedrijfsklaar handover. At each gate, confirm scope, budget, and safety.

Keep stakeholders aligned: owners, architects, engineers, and installers. Clear decision logs prevent drift and guard the quality of equipment. This is also when you verify that every component is designed for brewing beer and fits your overall system plan.

By the time you hand off, the line is documented and ready for audits and growth.

Sizing snapshot (example)

| Brewhouse (hL) | Turns/Day | Brew Days/Year | Annual Capacity (hL) | Typical Fermenters | Chiller (approx kW) |

| 20 | 2 | 300 | 12,000 | 6×40 hL + 2×20 hL | 120 |

| 30 | 2 | 300 | 18,000 | 6×60 hL + 2×30 hL | 180 |

| 50 | 2 | 300 | 30,000 | 8×100 hL + 2×50 hL | 300 |

| 100 | 2 | 300 | 60,000 | 12×200 hL + 4×100 hL | 600 |

Numbers are illustrative; always validate against real cycle times, styles, utilities, and local code requirements.

Chart: Illustrative Annual Capacity vs. Brewhouse Size (see plot above).

“Measure steam, water, power, and glycol early; drawings beat assumptions.” — senior project brouwer

Notes on planning language you will hear

In beer plants, we talk about bierbrouwen methods and apparatuur voor het brouwen van bier because every piece of equipment has a job. For a brewery setup, you want the right brewery with the right equipment that matches your brewing goals En production needs. Many ambachtelijke brouwers learned while een brouwerij beginnen that a reliable bierbrouwsysteem and clear piping design and installation shorten projects.

The hot side is built around giststarter, klaringskuip, ketel, and whirlpool to move wort to the cellar. The cold side turns quantities of beer into finished brands using each fermentor, bright tank, temperatuurregelingen een koelmachine loop carrying glycol. Utility planning and energy efficiency keep bills in check while automation En control systems support operators.

Hygiene and safety use sanitair fittings, a validated cip system, and at least one sanitary valve at low points. A clean floor makes the area safer and faster to clean on-site. Downstream, a flexible packaging system feeds distribution.

Every site is different. A microbrouwerij can use small batch methods in an existing facility; scale breweries lean on skids and pre-wired panels. Inside production facilities, brouwerijen are arranged with a sensible layout that suits the building. With careful installation and commission, you protect output and avoid downtime.

If you’re evaluating brouwoplossingen in the broader bierindustrie, compare warranties, quality of equipment, and support. The craft beer movement shows variety matters—plan fabrication details, match market demand, and verify the equipment is truly designed for brewing beer at the level of quality you promise.

FAQs

What approvals do I need before installing a commercial system?

In the U.S., you must obtain TTB approval (Brewer’s Notice) before operating, and you’ll file periodic operations reports thereafter. Local building, fire, and health permits also apply.

How do I size fermentation relative to the hot side?

Plan roughly 4–6× brewhouse volume in cellar capacity, mixing 1× and 2× unitanks for flexibility; actual ratios depend on styles and scheduling.

What’s the best way to keep lines sanitary?

Adopt validated CIP procedures, train people on chemicals and temperatures, and document verification steps (conductivity, ATP, or micro).

How should ventilation and drains be designed?

Provide sufficient exhaust over the boil and plan floors and drains for realistic wastewater volume and temperature.

Where can I find standard references on quality and lab space?

The Brewers Association publishes planning pieces for quality labs and other build considerations that are excellent starting points.

Sources and further reading

- Brewers Association: ventilation, cleaning, lab, and safety resources.

- Oxford Companion to Beer: definition and scope of CIP.

- TTB: Brewer’s Notice and operational reporting requirements.

- Capacity planning heuristics and building considerations (industry guides).

Key takeaways

- Size hot side, cellar, and utilities as a system; leave headroom for growth.

- Map a clean, safe layout with sanitary piping and validated CIP.

- Use focused automation and integrated controls to stabilize quality.

- Document utilities, drains, and ventilation early—drawings beat assumptions.

- Phase installation with water trials, then live beer; train people and lock SOPs.

- Build a realistic plan for packaging, QA, and material flow before launch.

- Keep permits and records current; design for maintainability and future expansion.

(We’re a manufacturing partner for customizable brewing equipment—designed, built, and supported for global projects. If you’d like an engineering chat or a fast sketch of your space, I’m happy to help.)