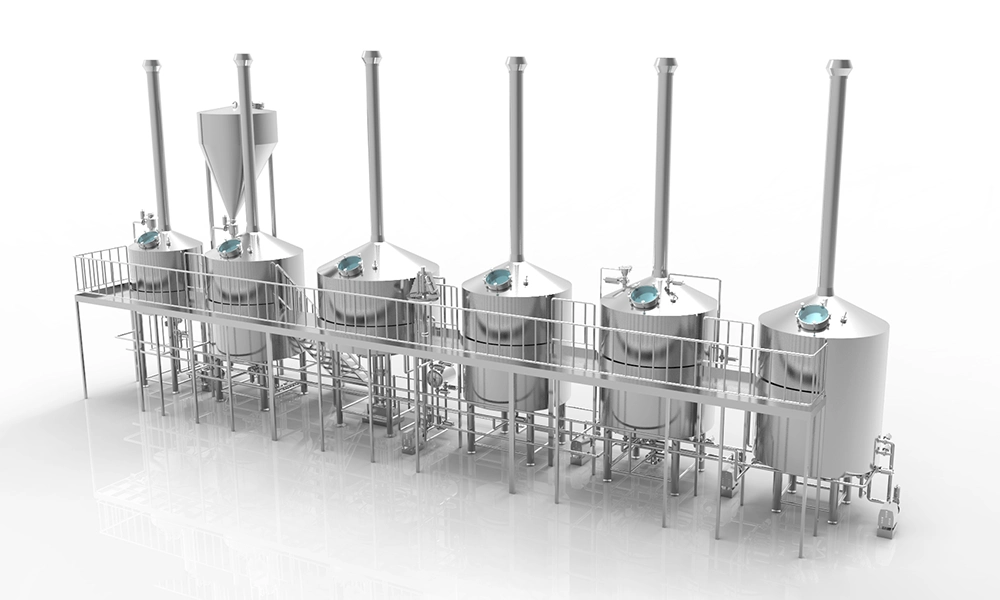

Every batch wort production capacity is 5000L, brewing 4~10 batches within 24 hours, and the monthly output is 160KL~400KL, the PLC control system can automatically store a variety of brewing recipes. The valve adopts a pneumatic butterfly valve, one-click operation for intelligent brewing. The volume of the fermentation tank is 10KL; the number: 12~30.

1. Systém varny

Mash Tun

Stirring: Stirring should use large-diameter and low-speed stirring blades, suspended reducer and can control the stirring speed by frequency conversion, so as to avoid the formation of turbulent flow on the liquid surface of the mash during stirring and reduce the oxygen absorption of the mash. It can be lower stirring according to equipment requirements.

Heating area and method: The design of the heating jacket should allow the heating steam to enter the jacket evenly, and at the same time prevents unsmooth draining of condensed water. Therefore, the jacket should be semi-circular tube type or honeycomb type, controlled in sections, steam inlet and condensate water outlet should be multi entry and exit, ensure enough heating area, and choose good quality drain valve.

The steam jacket will produce a large amount of condensed water, which can be completely recovered. It can be used as softened water for boilers (for equipment with relatively large production capacity, it is recommended to add pipeline of steam condensate water recovery system to save boiler energy consumption)

Lauter Tun

The total operation time should be controlled within 180min. The thickness of the spent grain layer is with in 220mm-400mm, which meets the needs of various varieties of craft beer. The entire filtration time is about 2 to 3 hours, and the speed of entering the mash should be lower than 1.2m/s.

The wort reflow port is located at the bottom or upper part of the tank, and it should be avoided that the wort absorbs oxygen and splash the wort layer during the reflow; the wort collection port is conical design, more than 1.2/m2, evenly arranged.

Sieve plate: It is a machine-milled sieve plate, the hole of the sieve plate is a trapezoidal design, the aperture width is 0.7mm, and the gap between the sieve plates and between the sieve plate and the tank body after installation is ≤0.7mm.

The raking knife is designed as a straight-line or cross-type raking arm, which should have rotation and lifting functions, and can be controlled continuously or in sections. The main shaft seal adopts a high-level seal, and the sealing surface is above the liquid level, which won’t be any leakage.

For grain washing outlet, it can be nozzle type or central distribution type, the design requires large flow without impacting the grain layer.

The liquid level control adopts the design of balance column (tank) or pressure difference to avoid the occurrence of the compaction of the spent grains layer.

Temporary Storage Tank

In order to achieve multi-batch brewing, a new temporary storage slot needs to be added.

Varná konvice

- The process parameters require that the head space is not less than 35% of the full volume. Boil time 60-100min. Evaporation strength within 8%–12%;

- The heating method adopts the internal heater with better effect;

- Set up the device for adding hops and accessories (such as dried tangerine peel, hemp pepper, honey, etc.).

Whirlpool Tank

The wort feeding speed is 3~5m/s and rotates counter-clockwise (clockwise).

The wort whirlpool clarifies the static time for 20min. Wort feeding time 12min.

The whirlpool tank uses centrifugal force and gravity to make the thermal coagulation and hop residue formed during boiling gradually gather in the center of the tank during the precipitation process to form a steamed bread-like sediment to achieve the purpose of solid-liquid separation.

There is a sloping bottom structure on the tank bottom structure, the entire tank bottom is inclined to the sewage outlet with a slope of 2%.

Wort Cooling

In the process of beer production, the cooling consumption of the hot wort cooling water is quite large, about 6000L of cold water, and the wort cooling adopts a thin plate heat exchanger. During this process, the hot wort and the cooling water are pumped in a turbulent form and flow countercurrently along the grooves on both sides of the grooved plate for heat exchange.

We adopt one-stage cooling method: use brewing water to cool the hot wort to the temperature of inoculating yeast at one time. The brewing water is first cooled to 2-4°C with glycol water, heated to 75-80°C after heat exchange with the hot wort, and the water can be directly recycled to the hot water tank.

2. Fermentation System

The cylindrical cone bottom fermenter can be used for pre-fermentation or post-fermentation alone, or it can be combined for pre-fermentation and post-fermentation in one tank. It has good adaptability, can also effectively reduce fermentation time and improve fermentation efficiency, and has been widely used in beer fermentation plants.

The cylindrical cone-bottom fermentation tanks are all made of 304 stainless steel plates. The upper head of the tank is provided with manholes, safety valves, pressure gauges, CO2 discharge ports, etc. The tank body is equipped with a complex cooling system. There is a stainless steel rotating spraying ball in the center of the upper part of the cone. The thermal insulation material is usually polyurethane foam, and the thickness is selected according to the local climate. For the washing of large fermentation tanks and wine storage equipment, use an automatic cleaning system. The system is equipped with lye tank, hot water tank, disinfection tank, acid tank and pipes and pumps for circulation.

The above is a brief discussion of the functions, characteristics and process parameters of brewhouse equipment, water treatment and fermentation. Generally speaking, a set of qualified equipment should be designed, manufactured and installed according to the characteristics of craft brewing, and only by fully considering the adaptability, cleanliness, high efficiency, oxygen avoidance, energy saving, safety and other factors of the equipment can it meet the needs of beer production.