Have you ever felt unsure about how to make high-quality spirits, essential oils, or even homemade fuel? You might have many questions about matériel de distillation. You may worry about safety, or you might ask: “How do I gather all the right tools, like pot stills and colonne de photos, or even reflux stills et essential oil distillers, without wasting money?” You’re not alone. Many people try to run home distilling kits and end up confused about distillation temperature, cuve d'empâtage setups, or measuring proof and abv. Some folks also wonder about legal compliance et distilling laws in different places. They may see complicated parts like fractionating columns, deflagmatorsou downcomer pipes and feel overwhelmed. Many just want to craft fine homemade spirits, or maybe do pure ethanol production, but fear they’ll miss vital steps in the distilling process.

Imagine spending hours—or even weeks—trying to build a moonshine still. You gather parts like a boiler for distillation, a distilling condenser, and a distilling thermometer. But then you get stuck. You don’t know how to maintain alambics en cuivre, how to handle the heads, hearts, tails, or how to plan a safe vinegar run. You hear about things like brandy distilling equipment, making whiskey at home with a parrot beak, or special gin stills that require a certain reflux ratio. Then more questions come up: “What about distilling safety? Could I cause an explosion if I skip the sas or lose track of the heat source (electric, propane, gas)?” Meanwhile, you read about licensing and see words like ATF / TTB or “distillers licensing.” You want to avoid big trouble, but you also want to enjoy a smooth spirit run. You might say to yourself: “Will I need a thumper keg, a spirit safeou steam distillation equipment pour herbal distillates? Or do I need a small fractional distillation setup for essential oil extraction?” Even if you get the hang of it, you might face scaling challenges. Should you move on to a commercial distilling equipment system or stick to a smaller design?

On top of all that, you check the market and realize it’s almost an $8.42 billion industry right now. You see équipement de distillerie artisanale in high demand, with a projected value of $18.23 billion by 2032. You also see that craft spirits have soared to $21.40 billion in 2023, growing fast each year. You might think: “Wow, so many people are already in the game. How do I catch up?” This doubt makes you question your choices, making the entire idea of distilling feel too confusing.

Don’t give up. You can get clear answers, plan a proper distillery set up, and even find top-quality systèmes de distillation that fit your needs. And guess what? You don’t have to figure it all out alone. You can leverage help from experts who know micro-distillery setups, large-scale designs, and everything in between.

Why Distilling Matters

Distilling is the act of purifying liquids by heating and cooling them. You can make spirits like whiskey, gin, or vodka. You can create homemade spirits or do pure ethanol production for fuel. You can also extract essential oils to make perfumes or natural remedies. A distillation apparatus includes parts such as a boiler / kettle, a condenser (Liebig, Worm Tub, Shotgun), and sometimes a colonne de reflux. If you care about flavor, you might opt for pot stills. If you want higher purity, consider colonne de photos ou reflux stills.

Here’s a quick reality check: the global distillation market is growing at about 7.3% each year. Alcohol distillation alone makes up around 45% of this market, while water purification, essential oil distillers, and industrial uses make up the rest. Asia-Pacific is rising fastest, with above 9% CAGR. North America holds around a 38% market share, thanks to the big craft scene.

Our Global Distillation Equipment Data & Analysis

Below is a helpful table with valuable data on the global distillation equipment space:

| Catégorie | Metric | Valeur | Significance |

|---|---|---|---|

| Market Size & Growth | 2023 Market Size | $8.42 billion | Baseline for industrial and craft demand. |

| 2032 Projected Market Size | $18.23 billion | ~7.3% CAGR (2023–2032). Fueled by craft spirits boom. | |

| Demand Segments | Alcohol Distillation Share | ~45% | Primary driver of equipment sales. |

| Essential Oil/Hydrosol Segment | Fastest-growing (12.1% CAGR) | Surging need for natural extracts in cosmetics and food. | |

| Regional Trends | Asia-Pacific Growth Leader | >9% CAGR | Boosted by fast-developing markets and rising distilled spirits demand. |

| North America Market Share | 38% | U.S. craft distilleries doubled to 2,300+ in just five years. | |

| Cost & Compliance | Home Distilling Kits | $200–$2,000 | Legal restrictions in many regions can slow market growth. |

| Commercial System Costs | $10,000–$500,000+ | Certification & compliance add 15–20% to costs. | |

| Case Study Impact | Small Craft Distilleries | 85% prefer modular <500L | Flexible for multi-spirit runs (e.g., whiskey, gin). |

| Safety Compliance | 60% want automated valves | Helps prevent accidents and ensures safer ethanol/fuel processing. |

Key Parts of Distilling Equipment

1. Boiler for Distillation

A boiler / kettle is where your mash or wash boils. Cuivre is popular because it helps remove sulfur. Stainless steel (304, 316) is also common for durability and easy cleaning. This vessel must hold enough liquid for your run. When picking boiler capacity, think about how much finished spirit you want.

2. Column Still and Pot Still

- Pot stills keep more flavor. They’re great for whiskey or brandy distilling equipment.

- Arrêt sur image du reflux ou colonne de photos raise purity. They include plates or copper mesh packing to manage reflux. You track something called the reflux ratio, which affects the final level of distillate purity.

3. Condensers and Cooling

A distilling condenser cools vapor back into liquid. Options include a worm tub condenser, a Liebig condenser, or a shotgun condenser. If you want to handle big volumes, you might need a cooling system for still with extra water capacity.

4. Special Components

- Thumper keg: Also called a Thumper (Doubler), used to boost ABV and refine flavor.

- Spirit safe: Collects your spirit so you can see clarity and volume.

- Parrot beak ou Parrot (Alcoholmeter Holder): Lets you see real-time proof as the spirit flows.

- Sas ou fermentation lock: Important for preventing contamination in your mash tun / fermenter.

The Distilling Process Step by Step

- Mashing & Fermentation: You cook grains to release sugar. Then you cool it and add yeast (Distiller’s Yeast, Turbo Yeast). The yeast ferments the wort to create wash. You might also use fruit for brandy or botanicals for gin.

- Stripping Run: A fast run to remove solids, sometimes giving you “low wines.”

- Spirit Run: Slower run to separate heads/foreshots, heartset tails/feints. The most flavorful and clean portion is called the hearts.

- Cuts & Collection: You must trim off undesirable fractions. This step can define the character of your final product.

- Aging: Some spirits rest in fûts de chêne to develop complexity.

- Filtration & Bottling: Some people filter their spirit to remove haze.

Overcoming Distilling Problems

Nettoyage et entretien

Cleaning stills is key. A typical first step is a vinegar run. Then you might do a sacrificial run with cheap wash. Vinegar (for cleaning) helps remove residue, while potassium metabisulfite sanitizes. Copper maintenance is also a must.

Distilling Safety

Always have safety valves or a pressure relief valve. Watch for leaks.

- Use a hydrometer (Proof, Mash) to measure alcohol content.

- Keep a thermometer to check temperatures.

- Make sure your water supply flows well for cooling.

Scaling up Distillation

Small batch distilling is fun for a hobby. You can use home distilling kits. But if you grow, you might want a commercial distilling equipment setup or a micro-distillery configuration. You’ll face laws about distillery licensing, le ATF / TTB in the U.S., or HMRC in the UK.

Distillation Methods (Simple, Fractional, Vacuum, Steam)

- Distillation simple: Basic separation. Great for a single separation step.

- Distillation fractionnée: Uses fractionating columns to achieve high purity in multiple stages.

- Distillation sous vide: Lowers boiling points. Helps with heat-sensitive products, like some essential oils.

- Steam distillation equipment: Ideal for herbal distillates and delicate essential oil extraction.

Showcase: Distilling Equipment In Action

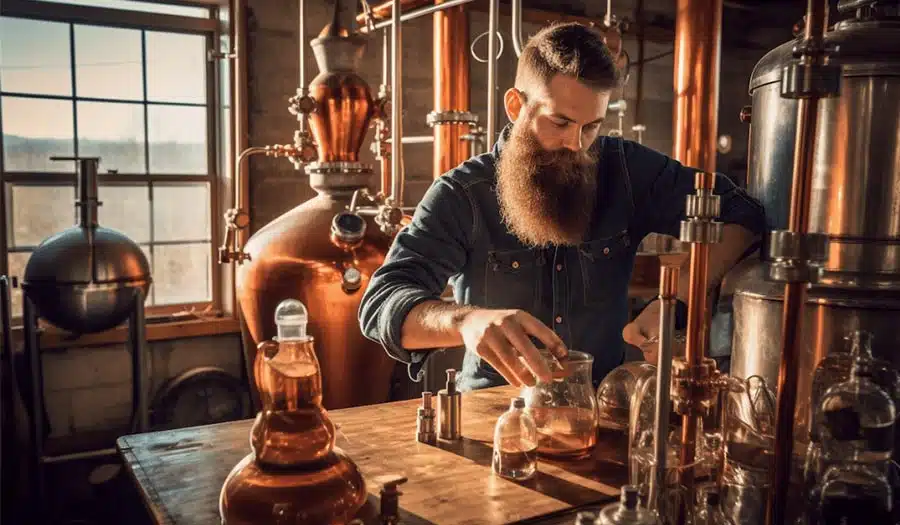

Picture a small family-run craft distillery. They do an initial sacrification (or saccharification) step for starch conversion, then ferment with alcohol yeasts. Next, they run a strip with a pressure cooker still. They do a second run in a 50-gallon copper alembic still. They focus on gin stills with a basket for botanicals (Juniper Berries – Gin). They test with a proofing hydrometer, watch heads, hearts, tails, and measure the final ABV. Over time, they age some product in fûts de chêne. They love the outcome, and you can do the same in your own workshop or at scale.

What If You Need More Than Distilling?

Micet offers a wide range of systems for breweries, wineries, plus matériel de distillation. We have built over 1,000 breweries and wineries across 86 countries, and we have 12 service centers around the world. Our track record shows we help folks move from small setups to advanced systems. We also provide strong after-sales support and we stand by our gear.

Micet strives to help you integrate everything from advanced distillation apparatus to specialized auxiliary machines like a distillery machine or even a beer filler machine. We use our robust experience to guide clients in conception de la brasserie, equipment procurement, and other professional engineering tasks. We are well-versed in cuves de fermentation, bright beer tank solutions, and can even handle unique requests for équipement de vinification or a versatile beer bottling machine.

If you’re ready to learn more, check out our pages on matériel de distillation or see how we tackle équipement de distillerie commerciale challenges. Our aim is to ensure every piece—like the boiler / kettle, fermenteur, or even the distilling condenser—works efficiently.

Global Market Growth and the Craft Spirit Movement

Craft distillery is huge. People love small-batch whiskeys, gins, rums, or brandies. This growth feeds the need for specialized parts like thumpers, bubble plates, or even specialized features like a dephlegmator.

- In 2023, the craft spirits market was $21.40 billion.

- Growth is expected to reach $115.45 billion by 2030.

- Many new distilleries use a micro-distillery model to test the market before ramping up.

Micet sees how large or small distillers face issues with equipment design or safety. Our engineering design services help them pick the best colonne de photos or optimize the ratio of heads, hearts, tails removal.

Action with a Trusted Partner

You want to start, expand, or optimize a distillery. You fear hidden costs, regulatory confusion, or messy results.

But it gets tougher. Each day you delay, you lose potential revenue or product. You might waste money on the wrong gear. Meanwhile, your competition surges ahead, mastering the perfect cuts and prime flavor.

Micet helps you skip the guesswork. We have 15+ years of experience. We combine R&D, production, sales, and top distilling accessories to give you a complete answer. All of that is built upon real success—over 1,000 breweries and wineries launched, 86 countries served, 12 offices on five continents, and a professional team with strong experience.

Frequently Asked Distilling Questions

- Can I Distill at Home? It depends on your local distilling laws ou distillers licensing. You might need special permits from agencies like ATF / TTB (U.S.) or HMRC (UK).

- What About Safety? Always ventilate well. Keep a sight glass if possible. Use a safety valve / pressure relief valve. Don’t run a still indoors without proper airflow.

- Which Materials Are Best? Cuivre helps remove unwanted sulfur. Stainless Steel (304, 316) is durable and easy to clean. Both can appear together in hybrid stills.

- What’s the Difference Between Steam Distillation and Reflux Distillation? Distillation à la vapeur is best for herbal distillates or delicate essential oils. Distillation à reflux focuses more on higher-purity alcohol, like vodka or gin.

- Do I Need a Thumper Keg? A thumper helps raise ABV and refine flavor. It’s popular for alcool de contrebande or some whiskey recipes.

Extra Tips

- Focus on the right size: “Scaling up distillation” is key if you plan to do more than small batches.

- Practice safe cleaning stills methods: a vinegar run first, then clean out with water.

- Check out distilling forums to learn from other hobbyists or professionals.

- Maintain a stable water supply for efficient cooling.

- If you are making making whiskey at home, consider how you’ll handle foreshots collection, spirit run, and final proofing.

A Glance at Distilling Terminology

| Term | Definition |

|---|---|

| Heads/Foreshots | The first portion of your run, high in unwanted compounds. |

| Hearts | The middle cut—clean, tasty spirit. |

| Tails/Feints | The final portion containing heavier flavors and fusel oils. Can be recycled into next runs. |

| Fractionating Columns | Columns with plates or packing used to refine the vapor, leading to higher ABV. |

| Reflux Ratio | The proportion of the condensed vapor that returns to the column vs. goes to collection. |

| Mash | The mixture of converted grain or other base materials before fermentation. |

| Low Wines | The output of the first distillation, often used for a second run. |

| Strip Run | An initial quick run to remove water and large solids. |

Craft Spirits Boom Pharmaceutical Distillation Essential Oils Demand Asia-Pacific Expansion Automation & Compliance

Alcohol Distillation: ~45% share (2023), whiskey, gin, vodka dominate.

Essential Oils/Hydrosols: Fastest-growing segment (12.1% CAGR).

Industrial Water Distillation: $5.6B (2022), strong in pharma/biotech.

Regional: Asia-Pacific >9% CAGR (led by India/China), North America 38% share (2023).

Regulatory Barriers: 30% of home equipment buyers face legal restrictions. TTB/ATF compliance adds 15–20% to commercial costs.

You can’t pick the right matériel de distillation or you feel stuck with home setups that lack reliability.

Time passes. Competitors get ahead. Costs mount.

Let an expert help. Micet offers custom systems, along with large or small solutions plus design support.

We do more than standard gear. Our brand includes knowledge on équipement de brasserie, cuves de fermentationet auxiliary machines to keep your entire operation smooth. Our service team, with 22 years of process design experience, ensures your project is correct from day one. Our CEO Nancy has 15 years of international sales experience, so you get top-level insights on your global distribution goals. Our production director has 13 years of experience, and our inspectors each hold 11 years in quality control.

Consider Combining Brewing and Distilling

Many breweries branch into distilling. With something like a matériel de distillation add-on, you can use leftover beer that did not pass the taste test and transform it into spirits. Some folks use spent grain in advanced ways or create an entire line of whiskey.

If you want more flexibility, check out alcohol distillery equipment for sale or see affordable distillery equipment that can help you start small. If you need a big jump, équipement de distillerie commerciale can serve large-scale operations.

A Quick Look at Micet’s Approach

We have:

- 12 service centers, worldwide.

- A track record in 86 countries.

- Over 1000 breweries and wineries set up with our help.

- 15 years of continuous learning.

- 3-year warranty on tanks, 1-year warranty on accessories.

But we don’t just pump out stills. We ask: “Do you need a small home distilling kit or a giant production line with a big boiler capacity?” Then we adapt. We also support you once you’re up and running, so you’re not left alone with a huge still and no clue about cleaning stills or meeting local laws.

Common Distilling Mistakes

- Skipping the Vinegar Run: This can leave harmful residue in your system.

- Ignoring Safety Valves: Risking pressure buildup—dangerous.

- Rushing the Cuts: Overlapping too many compounds can ruin your flavor or cause headaches.

- No Reflux Management: You must adjust your cooling system for still to get the right reflux ratio.

- Poor Maintenance: Letting metal parts (especially cuivre sections) corrode.

Why the Right Equipment Matters

- Flavor Quality: Good pot stills ou copper alembic stills help remove off-flavors.

- Efficacité: A robust distillation apparatus yields more delicious hearts.

- Évolutivité: With the right design, you can jump from 5 gallons to 500 gallons.

- Legal Compliance: Certified parts make it easier to pass inspections.

Make the Leap with Confidence

You’re done with confusion. You know about cuve d'empâtage, fermentation locket steam distillation equipment pour essential oil extraction. You see how a worm tub condenser works vs. a shotgun condenser or a Liebig condenser. You’ve read about bubble plates, lyne arm, and how to do a pressure cooker still run. You also can watch your distilling thermometer and track the spirit with a proofing hydrometer.

It’s time to act. The market is large, with essential oils, rum distillation, vodka distillation, and more fueling growth. Micet makes the journey simpler by offering integrated solutions that cover everything from a small micro-distillery to a big spirit distillation facility.

Action Steps

- Make a Plan: Decide whether you want a small or big system.

- Contact Experts: Lean on proven help to avoid beginner mistakes.

- Review Tools: Clarify if you need a fractional distillation system, a vacuum distillation setup, or a simple distillation still.

- Start Small: A home distilling kit can teach you the basics.

- Scale Up: Move to a commercial distilling equipment solution when you’re ready.

Wrap-Up

Distilling can be fun, profitable, or both. And it is open to hobbyists as well as large firms. You only need to pick your path and gather the right distilling accessories. That could be a thumper keg, a deflegmator, or a drip tip for advanced fractioning. Your end product might be whiskey, rum, gin, or a precious essential oil. Along the way, be mindful of safety, use quality raw inputs like grain (corn, barley, wheat, rye), and keep an eye on details such as spirits filter ou yeast nutrients.

Micet helps you do all that and more. We can guide your distillery design from start to finish. Our 15 years of experience let us help you gain confidence in the face of so many big steps. We look at your unique goals, whether you want to produce making whiskey at home or jump into big commercial productions. And with our broad network, including large support offices in many countries, we can respond fast to keep your project on track.

If you’re ready to see how we can help, check out our matériel de distillation page. Or dive deep into équipement de distillerie commerciale or even alcohol distillery equipment for sale for bigger operations. We look forward to supporting your distilling dream.

Embrace your next step. Explore, learn, and distill your way to success with the right gear, guidance, and system design. Let’s do it together.