You want clean, consistent wine, batch after batch. Oxygen, unstable temps, and hard-to-clean vessels make that tough. A ステンレス鋼 wine tank with modern controls fixes these pain points fast.

A wine fermenter stainless steel vessel is a food-grade ステンレスタンク designed for precise wine fermentation. It delivers stable temperature via a cooling ジャケット, smooth sanitation, tight oxygen control, and easy racking of セジメント. Compared with plastic or wood, ステンレス製ワインタンク are durable, お手入れ簡単, and built for quality wine and repeatable results.

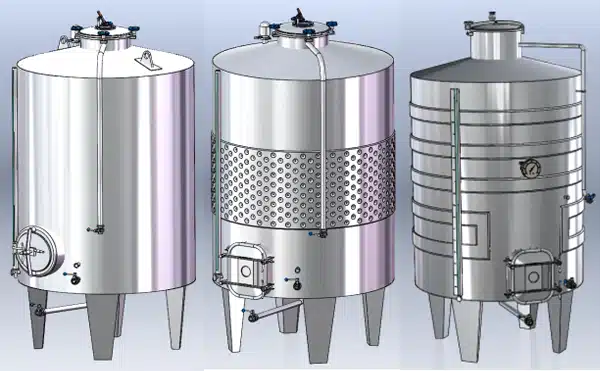

[Image Placeholder: stainless steel wine tank with cooling jacket, floating lid, thermowell, and tri-clamp ports]What is a stainless steel wine tank and why do winemakers choose it?

A ステンレス鋼 タンク for wine is a sealed, food-grade vessel tailored to the 醸造 そして 発酵 stages. Compared with a bucket fermenter または carboy, a stainless steel wine fermenter gives you controllable temperature, hygienic surfaces, and precise valving for ラック and transfers. It’s the modern backbone of a small ワイナリー or large cellar.

If you’re outfitting or upgrading a cellar, explore complete ワイン醸造設備 to match tank sizes, pumps, and fittings across the line.

How does wine fermentation behave in a stainless steel fermenter?

During 発酵, yeast converts sugars to alcohol and CO₂. A ステンレス製発酵槽 keeps the inside of the tank sanitary and neutral, preserving delicate fruit while your 発酵プロセス runs at a stable temperature. This is why tanks are ideal for aromatic white wine and consistent reds.

For larger builds, see purpose-built ステンレス製ワイン発酵タンク, which integrate thermowell, pressure gaugeそして クーリングジャケット options for tight control.

“Stability in temperature and oxygen is the quickest path to repeatable quality.”

Temperature Stability (°C, lower is better)

Stainless steel jacketed: |█████████| ±0.3

Plastic carboy: |█████ | ±1.5

Oak barrel (ferment): |███████ | ±0.8

Variable capacity wine tanks vs fixed volume: which fits your batches?

Variable capacity wine tanks (a.k.a. variable capacity tanks) use a floating lid and inflatable gasket to seal any fill level—perfect for trial work, changing harvests, or 小ロット projects. A floating lid allows for variable volume control without excessive headspace. Add an エアロック to vent CO₂ and protect flavor.

For a flexible cellar footprint, review wine fermenter stainless steel options と pump for variable capacity, hand pumps for lid inflation, and interchangeable stainless steel lid assemblies.

Conical vs flat bottom: how do you manage sediment and racking?

A コニカル発酵槽 encourages セジメント to collect at the cone. With an upgraded tri-clamp racking arm そして tri-clamp butterfly valve, you draw clear wine while leaving lees behind. A flat bottom タンク is simpler and stacks well; add a racking port to ラック cleanly. Both styles can be jacketed and instrumented.

If you’re crossing over from beer, compare cellar-grade ビール発酵器 configurations; the fittings (cone angle, ball valve, and CIP) mirror what works in wine.

Cooling jacket, heating and cooling: why temperature control pays off

Yeast performance rides on temperature. A ジャケット or dedicated クーリングジャケット maintains a stable temperature; gentle heating and cooling ramps help finish sluggish ferments without stressing yeast. Add a 温度計 or PT100 in the thermowell to log data and drive automation.

Building out a larger system? Match your tanks to glycol loops and controls using modular 醸造設備販売—the same backbone that stabilizes beer stabilizes wine fermentation too.

Material matters: 304 stainless steel, sanitary welds, and food-grade design

Quality vessels start with 304ステンレス and sanitary TIG weld finishes. We specify 304ステンレススチール製 and passivated surfaces; every product contact part is made from 304 stainless steel そして made of stainless steel gaskets, ferrules, and dip-tubes. This 級ステンレス鋼 resists corrosion from acids and cleaning agents and stays 衛生的 for the long haul.

Done right, you get the perfect stainless steel interior for fruit purity, with fewer off-flavors and fast turnarounds between lots.

Sizing your tank: from homebrew to commercial batches

Whether you’re running pilot lots or full harvests, size your タンク to your grapes and the desired gallon batches or liters. Here are common points—from 5 gallon への 200l to cellar scale:

| ユースケース | 典型的なサイズ | 備考 |

|---|---|---|

| Trial lot (home-scale) | 6 gallon, 9 gallon, 14 gallon total capacity | Great for yeast trials and experimental blends; often bucket fermenter or mini ステンレスタンク |

| Small production | 200l | Ideal for micro-ワイナリー and boutique programs |

| Restaurant/brewpub hybrid | 500–1000 L | Flexible for “house” wine and production and storage in one facility |

| Growing commercial | 2,000–10,000 L | Integrate multiple zones and storage and fermentation in one line |

| Large cellar | 20,000–50,000 L | Dedicated tanks and processing equipment, smart manifolds |

For pilot tanks and training systems, see ナノ醸造設備 that adapts to wine R&D workflows.

Ports, valves, and fittings: what should your specification include?

Look for tri-clamp ferrules, a sample valve, a CIP spray ball, a side manway, and bottom discharge. A mid-height racking port with an adjustable arm helps you pull clear wine. Pair with a ball valve または tri-clamp butterfly valve as needed. Add a 1.5″ port for a pressure gauge (low-pressure) and a dedicated thermowell for your probe.

Cross-reference wine and beer fittings on a modern ビール発酵槽 to streamline spare parts and SOPs.

From wine to cider, kombucha, and bright beer: multi-product versatility

A clean ステンレス鋼 タンク is a utility player. It can run as a cider fermenter, hold a bright beer tank, or serve as a 紅茶 vessel. If you know the spike brewing conical format—or the spike conical range—the idea is similar: easy CIP, consistent geometry, and dependable ports.

Thinking beyond grapes? Compare a dedicated コンブチャ抽出容器 to ensure the right fittings, screens, and valve layout for tea solids.

Storage tank or fermenter: can one vessel do both?

Yes—with the right features. A jacketed 貯蔵タンク can work for aging wine, wine storage, and cold stabilization, while a matching fermenter handles the heavy lifting during primary. Many cellars use a “universal tank” strategy for production and storage, swapping ports and adding a floating or sealing lid as required.

If you need one line that can flex between storage and fermentation, review winery-grade ステンレス製ワイン発酵タンク with compatible CIP and manifold connections.

Cleaning and care: easy to clean, fast to turn

Stainless interiors are お手入れ簡単 with CIP cycles: rinse, caustic, acid, and final rinse. Inspect every gasket そして lid O-ring, verify weld seams, and confirm drains run clear. Keep a log for each タンク—you’ll catch issues before harvest. New stainless steel benefits from initial passivation; repeatable sanitation is what delivers quality wine.

Pro tip: after hot caustic, let the vessel cool and sanitize before sealing; always purge headspace on partial fills.

Case study: adopting stainless steel variable capacity wine tanks in a boutique cellar

A 30-acre estate swapped mixed plastic and older stainless for stainless steel variable capacity wine tanks. They chose two 1,500 L universals, four 200l pilots, and a jacketed primary stainless steel fermentation tank. Using an inflatable-seal lid, they ran variable volume lots post-press. Result: faster turnaround, 18% shorter primary, and tighter SO₂ management.

They had used a Marchisio style before; the new lineup mirrored marchisio variable features—inflatable rings, hand pumps, and quick-swap バルブ kits—but upgraded to heavier shells and manifolds. The team reported better color retention, smoother winemaking process flow, and lower losses at ラック thanks to the cone and racking arm.

Specs checklist for stainless steel wine fermentation tanks

Below is a compact checklist you can lift into your RFQ. The bolded terms are common spec lines buyers ask for:

- 素材: 304ステンレス shell and components (made from 304 stainless steel, food-contact surfaces passivated)

- 建設: sanitary TIG weld; polish to 2B or better

- ジオメトリ: 円錐形 または flat bottom as required

- Insulation/Jacket: dimple ジャケット zones for heating and cooling (glycol); optional cone jacket

- Ports: CIP, manway, sample, racking with upgraded tri-clamp racking arm, drain with tri-clamp butterfly valve

- コントロール: thermowell, RTD, pressure gauge (low-pressure), sight level

- Lids: sealed or floating lid with inflatable gasket そして エアロック; spare stainless steel lid recommended

- Capacities: pilot to large cellar (gallon total capacity or liters), include 10 gallon batches and pilot gallon batches options

- 品質: 高品質ステンレス鋼 finish; traceability; hydro test

- コンプライアンス: food safety documentation, weld maps, and CIP validation

Need a quick reference on core vessels? This ビール発酵槽 overview shows port layouts shared across wine and beer.

Home and pilot scale: 5 to 14 gallon total capacity (and beyond)

At the small end, wine fermenters can be 5 gallon, 6 gallon, 9 gallonそして 14 gallon total capacity for teaching, R&D, and micro lots. They’re perfect for gallon batches that prototype blends, yeast, or oak strategies before scaling.

If you’re bridging into pro gear, start with a ステンレス鋼 mini fermenter, then move to capacity stainless steel wine pilots like 200l tanks as your program grows. For compact, modular pilots, see ナノ醸造システム adapted to wine trials.

The broader system: from tanks to pumps and filling

あなたの タンク is part of a larger ecosystem—glycol chillers, transfer pumps, hoses, and mobile manifolds. Barrel work still matters for maturation, but stainless covers primary wine production with repeatable hygiene. Pair your tanks with compatible tri-clamp fittings; many breweries and wineries standardize lines so tanks and processing equipment share spares and methods.

For end-to-end coverage—including bright vessels and finishing—review bright beer tanks for sale if you also carbonate or clarify crossover products.

よくある質問

Are stainless steel wine fermentation tanks neutral in flavor?

Yes. A ステンレス鋼 タンク is neutral, highlighting fruit. Use oak alternatives or barrels later if you want wood tones. In primary 発酵, neutrality plus control usually yields cleaner aromatics.

What grade should I select—304 or 316?

304ステンレス is standard for wine. 316 offers higher chloride resistance but costs more. For most cellars, 304ステンレススチール製 is the right value.

Can one vessel handle both fermentation and storage?

Yes. Many run storage and fermentation in the same jacketed vessel with the right lid, ports, and insulation. A dual-purpose 貯蔵タンク can cold-stabilize, clarify, and hold finished wine.

Do variable capacity tanks risk oxidation?

Used correctly, no. The floating lid そして gasket seal headspace; add an エアロック and blanket with inert gas. Keep seals clean and check pressure regularly with simple hand pumps.

What about home makers—should I upgrade from a carboy?

If you want tighter temp control and faster CIP, yes. A small ステンレス鋼 fermenter may outperform any fermenter on the market at that size for speed of sanitation and durability.

Are conicals only for beer?

No. Wine 円錐形 vessels minimize lees loss and speed settling. Designs familiar from beer (e.g., a Spike Brewing conical) translate well to wine layouts.

Quick glossary (one-liners you can copy into SOPs)

- 発酵タンク: primary vessels that control heat and oxygen (use this exact term once for clarity).

- ワイン発酵タンク: purpose-built wine vessels with cooling and sanitary features.

- Stainless steel wine fermentation: clean, neutral fermentation inside a controlled タンク.

- Stainless steel variable capacity wine systems: seal at any fill level with a floating lid.

- Stainless steel variable capacity wine tanks: flexible vessels for changing batch sizes.

- Stainless steel wine fermentation tanks: cellar-grade vessels that deliver repeatability.

- ステンレス製発酵タンク: general term across wine, cider, and kombucha.

Summary—what to remember

- ステンレス keeps wine clean, consistent, and controllable.

- Match タンク geometry (cone or flat bottom) to your racking plan.

- Use a クーリングジャケット そして thermowell to hold a stable temperature.

- 選ぶ variable capacity wine tanks if your lot sizes change.

- Specify 304ステンレス, sanitary welds, and robust ports/valves.

- Plan the whole line—tanks and processing equipment, pumps, and controls.

- Start small (5–14 gallon total capacity, 200l) and scale with data.

- Keep CIP simple, seals tight, oxygen low—great quality wine follows.

- As a brewing-and-winery equipment manufacturer, we help size, instrument, and commission systems that fit your grapes, space, and budget—so your cellar makes better wine with fewer surprises.