Key Variables to Consider For Equipment Supplier Selection

| Parâmetros |

Critérios de avaliação |

Questions to Ask |

| Reputation and Track Record |

Number of years fabricating |

How long have you been supplying micro breweries? How many have you equipped? Request referrals. |

| Offering Suitability |

Vessels and systems align with business plan and budget |

Do your standard packages meet my specifications and budget? Where is flexibility vs customization possible? |

| Quality and Lead Time |

Build robustness, components, warranty, factories used |

What grade stainless steel do you use? What quality checks during manufacturing? What is standard lead time? Rush fees? |

| Order Fulfillment and Shipping |

Responsiveness to queries, proactive updates and delivery process |

How responsive are you during vessel fabrication and delivery? How are shipping damage claims handled? |

| Instalação e colocação em funcionamento |

Level of inclusion for installation supervision, operator training, calibrations etc |

To what extent is installation included? Is operator training provided onsite? What documents are handed over? |

| Ongoing Service and Support |

Response time, preventative maintenance contracts, troubleshooting assistance |

What are the routine maintenance requirements? What is cost for annual servicing? What troubleshooting assistance resources do you provide? |

Be sure to get bids from at least 3 vendors and ask lots of specific questions to evaluate fit for purpose. Give importance to quality, support and shared vision for growth over just capital cost alone.

Pros and Cons of Buying New vs Used Brewing Equipment

A major purchasing decision for new nano or micro brewery setups is whether to invest in brand new equipment or look for used vessels and hardware. While used equipment seems attractive from an upfront price perspective, it does come with higher risks around reliability and lifecycle that should be carefully evaluated.

New versus Used Brewery Equipment Comparison

| Parâmetros |

New Brewery Equipment |

Used Brewery Equipment |

| Custo do capital |

Highest upfront price |

Lower upfront price point |

| Tempos de espera |

12-16 weeks or more |

Ready for pickup immediately |

| Provenance |

Complete paperwork and certification |

Limited records, verbal assurances |

| Vida útil |

15-20 years guaranteed |

5-10 years expected life remaining |

| Fiabilidade |

Highest, meets latest standards and precision |

Greater uncertainty on vessel conditions |

| Energy Efficiency |

Latest insulation and steam/glycol delivery efficiency |

May have older energy wasting designs |

| Automation and IoT |

Latest sensors, data logging and analysis |

Typically more manual operation |

| Facilidade de manutenção |

Complete documentation and trained technicians |

Limited support records and availability |

| Unique Design |

Fully customized options |

Limited ability to tailor |

| Financing |

Full range of buying options like leasing and loans |

Fewer financing offers |

| Resale Value |

Holds higher residual value over decades |

Depreciates faster, limited buyers |

Recommendation: Being a long-term investment, opt for new equipment that aligns with business plan rather than short-term savings on used hardware which can create quality and servicing headaches later. Partner early with reputed suppliers who understand expansion plans to create modular solutions with some built-in future proofing on automation.

Diferentes capacidades de produção

The main difference between a microbrewery and a nano brewery is the production. By regulation, microbreweries must produce less than 15,000 barrels of beer per year.

A nano-cervejaria é mais pequena do que uma microcervejaria, com um limite de volume de 3 barris por lote.

Uma fábrica de cerveja piloto tem normalmente uma produção de 2.500 barris ou menos por ano. Os Brewmasters utilizam fábricas de cerveja piloto para duas razões: experimentação de receitas e lotes de teste antes de passar a uma produção maior.

Custo de arranque diferente

O custo de arranque de uma nano-cervejaria pode ser surpreendente, o custo médio de arranque de uma nano-cervejaria é de cerca de $30.000, e o custo máximo de arranque é de cerca de $60.000. Em circunstâncias normais, o preço do equipamento de microcervejaria situa-se entre 30 000 e 80 000 dólares americanos.

Para a produção de cerveja em casa, utilizando refrigeradores, velhos tanques de fermentação de plástico, barris de kimchi e muitos utensílios de cozinha, além de alguns produtos profissionais (como moinhos de grãos, pulverizadores, refrigeradores de mosto de bobina de cobre, etc.), a despesa em dinheiro para a produção de cerveja é apenas É 300-500 dólares americanos.

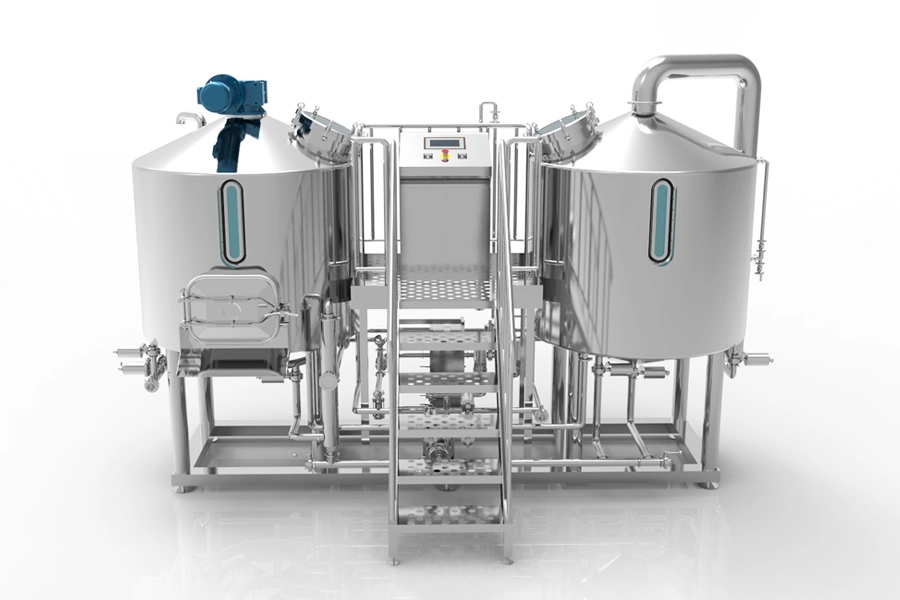

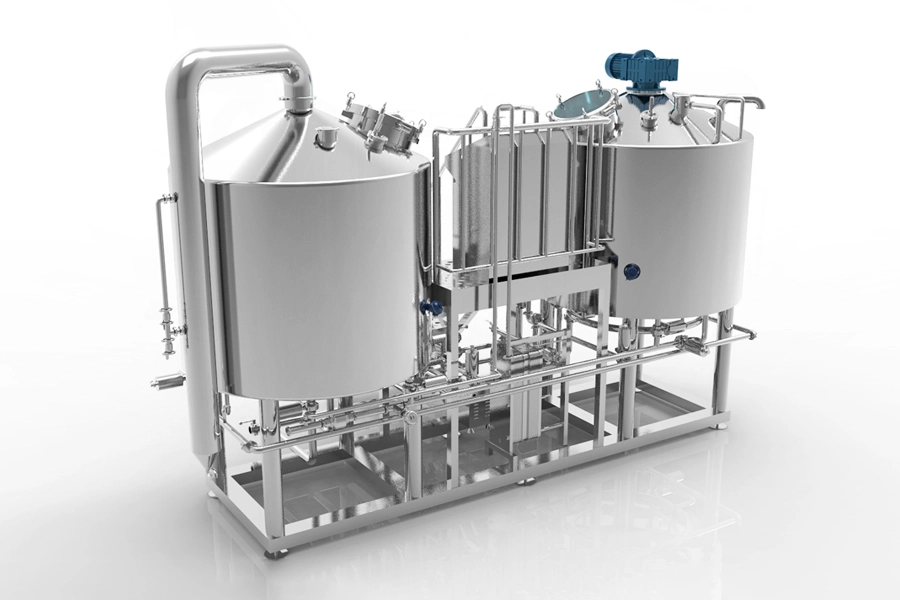

O equipamento Micet Nano Brewery está disponível para venda em todo o mundo.