¿Es usted crear una fábrica de cerveza o intentando haga crecer su negocio? Finding the right equipment can feel overwhelming. Many brewers struggle with picking gear that fits their space, budget, and beer styles. When equipment doesn’t match your needs, it can lead to wasted money, inconsistent beer quality, and production delays.

Think about what happens when your brewing system can’t keep up with demand. Customers wait longer, your brand reputation suffers, and growth stalls. Even worse, poorly chosen equipment might require expensive repairs or complete replacement within just a few years.

Afortunadamente, existen soluciones personalizadas que abordan estos retos habituales de la fabricación de cerveza. Con el socio adecuado que entienda tanto la ciencia cervecera como la ingeniería de equipos, podrá construir una fábrica de cerveza que funcione sin problemas y produzca siempre una gran cerveza.

¿Por qué es importante un buen equipo de cervecería?

Un buen equipo de cervecería te ayuda:

- Visite cerveza consistente

- Consumir menos energía

- Ahorrar dinero con el tiempo

- Haga crecer su negocio

- Mantener la seguridad de los trabajadores

En la actualidad, el mercado mundial de equipos para cervecerías tiene un valor de 1.000 millones de euros. $24.300 millones y creciendo a un ritmo de 7,5% cada año. Este crecimiento muestra el número de cerveceras que están empezando o expandiéndose en todo el mundo.

Equipamiento clave para cualquier cervecería

Componentes de la sala de cocción

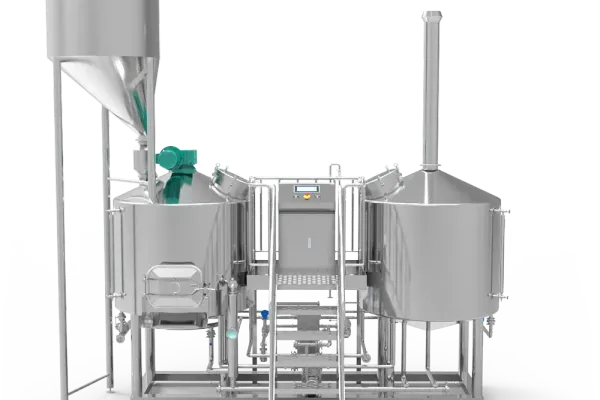

La sala de cocción es el corazón de su cervecería. Here you’ll find:

- Cuba de maceración: Donde los granos se mezclan con agua caliente

- Túnel de filtrado: Separa el mosto líquido del grano

- Hervidor de agua: Hierve el mosto con lúpulo

- Tanque de hidromasaje: Elimina materiales sólidos

Una sala de cocción completa de 10 BBL cuesta entre $120,000-$250,000 cuando son nuevos, pero puede ahorrar 30-50% comprando equipos usados.

En Micet, nuestros Equipo de microcervecería 10BBL de 2 recipientes combina la cuba de maceración y la cuba de filtración en un solo recipiente, lo que le permite ahorrar espacio y dinero sin perder calidad.

Equipos de fermentación y acondicionamiento

Después de la sala de cocción, la cerveza debe fermentar:

- Fermentadores cónicos: Depósitos cónicos donde la levadura transforma el azúcar en alcohol

- Unitanks: Depósitos polivalentes para fermentación y acondicionamiento

- Depósitos Brite: Para carbonatar y almacenar la cerveza terminada

- Sistemas de refrigeración por glicol: Mantiene la fermentación a la temperatura adecuada

Un fermentador de 10 BBL cuesta $8,000-$15,000 nuevos. Los depósitos usados pueden ser 20-40% más baratos si los encuentras buenos.

Nuestra Tanque de fermentación de acero inoxidable y tanques brillantes están hechos para durar más de 15-20 años con los cuidados adecuados.

Equipos de envasado y dosificación

Para hacer llegar la cerveza a los clientes, necesitas:

- Líneas de enlatado/embotellado: Poner cerveza en paquetes

- Lavadoras de barriles: Barriles limpios para su reutilización

- Sistemas de calado: Servir cerveza directamente

Una línea básica de enlatado cuesta $150,000-$500,000 pero reduce enormemente los costes de mano de obra en comparación con el envasado a mano.

Elegir el equipo del tamaño adecuado

| Tamaño de la cervecería | Capacidad de producción | Espacio típico necesario | Coste total estimado |

|---|---|---|---|

| Nano | 1-3 BBL | Más de 1.000 pies cuadrados | $50,000-$150,000 |

| Micro | 7-15 BBL | 3.000-5.000 pies cuadrados | $250,000-$500,000 |

| Grande | 30+ BBL | Más de 8.000 pies cuadrados | $1 millón+ |

Muchas cervecerías empiezan siendo pequeñas pero quieren crecer más adelante. Nuestra Sistema de fabricación de cerveza en pequeños lotes de 500 litros ofrece un punto de entrada asequible con margen de expansión.

La calidad del material importa

El mejor equipamiento para cervecerías Acero inoxidable 304 o 316. Estos materiales:

- Don’t rust

- Don’t affect beer flavor

- Se limpia fácilmente

- Duran muchos años

Racores Tri-clamp facilitan la conexión y desconexión de piezas para su limpieza.

Facilitar la limpieza

Los sistemas de limpieza in situ (CIP) ahorran tiempo y agua. Los:

- Reduce el tiempo de limpieza en 25%

- Utiliza 50% menos agua

- Garantizar un saneamiento coherente

Según datos del sector, 65% de las fábricas de cerveza utilizan actualmente algún tipo de automatización CIP.

Caso práctico: Éxito del crecimiento de una cervecería

A small brewery started with a 7 BBL system and soon found they couldn’t keep up with demand. Their beer was popular, but they had to turn away orders.

Tras cambiar a una sala de cocción automatizada de mayor tamaño, aumentaron la producción en 1.000 millones de euros. 300% y recuperaron su inversión en sólo 18 meses.

Cómo la tecnología mejora la fabricación de cerveza

El equipamiento de las cervecerías modernas suele incluir:

- Paneles de control: Control y ajuste de las condiciones de elaboración de la cerveza

- Bombas VFD: Cambie las velocidades de flujo según sea necesario

- Software de elaboración de cerveza: Seguimiento de recetas y datos de producción

Estas tecnologías pueden reducir la variación de los lotes y mejorar la coherencia.

El coste de abrir una cervecería

Starting a brewery isn’t cheap. Here’s what to expect:

- Equipamiento: 40% de los costes totales

- Edificio/espacio: 20-30%

- Permisos/licencias: 5-10%

- Ingredientes iniciales: 5%

- Otros gastos: 15-30%

Los costes ocultos suelen incluir:

- Instalación

- Trabajos de fontanería y electricidad

- Formación del personal

Nuestra Sistema de elaboración de cerveza de 1000L ofrece un gran valor para las nuevas cerveceras que cuidan su presupuesto.

Buenas prácticas de mantenimiento

Un buen mantenimiento hace que su equipo dure más:

Tareas diarias

- Comprobar los sensores de temperatura

- Limpiar residuos visibles

- Inspeccionar juntas y retenes

Tareas semanales

- Limpieza profunda de las líneas de glicol

- Probar los sensores de pH

- Inspeccionar las bombas

Errores comunes que hay que evitar

- Omisión de la calibración del sensor de pH

- Mal diseño del sistema de glicol

- Adquirir depósitos demasiado pequeños para sus necesidades

Principales proveedores de equipos

A la hora de elegir los equipos, tenga en cuenta estas marcas de confianza:

- DME Process Systems (soluciones llave en mano)

- Operaciones de elaboración de cerveza Alpha (centradas en la automatización)

- Sistemas mecánicos específicos (sistemas más grandes)

- Micet (soluciones a medida con más de 15 años de experiencia)

Micet destaca por ofrecer tanto sistemas estándar como sistemas totalmente sistema de elaboración de cerveza automatizado opciones.

Energía y sostenibilidad

La fabricación de cerveza consume mucha energía:

- Los costes energéticos suponen 8-12% de gastos de cervecería

- La refrigeración por glicol y las calderas de vapor consumen 60% de energía de la fábrica de cerveza

- La fabricación de cerveza con energía solar puede reducir los costes energéticos en 30%

Nuestros diseños energéticamente eficientes ayudan a reducir estos costes continuos.

Vida útil del equipo

¿Cuánto durará su equipo?

- Fermentadores de acero inoxidable: 15-20+ años

- Enfriadoras de glicol: 10-15 años

- Líneas de conservas8-12 años

- Embotelladoras manuales: 5-7 años

La compra de equipos de calidad se amortiza con el tiempo, con menos sustituciones y reparaciones.

Opciones de equipamiento especial

Más allá de la elaboración de cerveza básica, es posible que necesite:

- Equipos de destilación para la producción de bebidas espirituosas

- Equipo de kombucha para té fermentado

- Sistemas móviles de elaboración de cerveza para mayor flexibilidad

Nuestra Equipos de destilación de alta calidad para microdestilerías y destilerías comerciales y Tanque de fermentación de Kombucha le permiten ir más allá de la cerveza tradicional.

Equipamiento para cervecerías artesanales

Desglose del coste de los equipos

Vida útil del equipo

Preguntas frecuentes

¿Puedo construir mi propio equipo de cervecería?

Sí, pero sólo para lotes muy pequeños. Los equipos de bricolaje suelen provocar contaminación y resultados irregulares. Los equipos profesionales garantizan la seguridad y la calidad.

What’s the lifespan of stainless steel fermenters?

Con los cuidados adecuados, 15-20 años o más. Un mantenimiento regular y una limpieza adecuada marcan una gran diferencia.

¿Cuánto espacio necesito para una fábrica de cerveza?

Nano breweries need at least 1,000 square feet. A 15 BBL system typically requires 5,000+ square feet. Always plan for more space than you think you’ll need.

¿Es el material usado una buena opción?

Los equipos usados pueden ahorrar 20-50% en costes, pero inspeccione con cuidado si presentan daños, desgaste o faltan piezas. Los fermentadores y las lavadoras de barriles son compras de segunda mano más seguras que los componentes electrónicos.

Planificar la instalación de su fábrica de cerveza

A la hora de diseñar su fábrica de cerveza, tenga en cuenta:

- Flujo de trabajo: ¿Cómo se moverán los materiales y la cerveza por su espacio?

- Crecimiento: ¿Necesitarás añadir tanques o mejorarlos más adelante?

- Servicios: ¿Tienes suficiente electricidad, agua y desagüe?

- Presupuesto: What’s most important now vs. what can wait?

Nuestro equipo de ingenieros puede ayudarle a crear una disposición personalizada que maximice su espacio y eficiencia.

Elegir el equipo adecuado

Choosing brewery equipment is one of the biggest decisions you’ll make. The right system will:

- Elabora los estilos de cerveza que quieras

- Se adapta a su espacio y presupuesto

- Permitir el crecimiento futuro

- Proporcionan años de servicio fiable

Con más de 15 años de experiencia en la creación de sistemas de elaboración de cerveza, Micet entiende estos retos. Nuestro 2000L 3 Recipientes Equipo de Microcervecería representa el equilibrio perfecto entre calidad, eficacia y valor para las cervecerías en expansión.

Conclusión

Encontrar el equipo cervecero adecuado requiere una planificación cuidadosa, pero sienta las bases de su éxito cervecero. Si conoce sus necesidades, su presupuesto y sus planes de crecimiento, podrá seleccionar el equipo que le será útil durante muchos años.

Whether you’re starting small with a Sistema de fabricación de cerveza en pequeños lotes de 300 litros o construir una 30HL Equipo de cervecería comercial de 5 recipientes operation, quality equipment is an investment in your brewery’s future.

The craft brewing industry continues to grow, with the global equipment market expanding at 7.5% annually. By choosing experienced partners who understand both brewing science and equipment engineering, you’ll be well-positioned to create great beer and build a successful business.