Dreaming of starting your own brewery but overwhelmed by the details? Confused about the right equipment, cost, or even how to brew your first great beer? This guide walks you step-by-step through every stage of a successful micro brewery setup, helping you avoid common pitfalls and get your brewery off the ground.

How do you set up a micro brewery?

To set up a micro brewery, create a business plan, select the right micro brewery equipment, design your brewing system layout, and follow an optimized brewing process for craft beer. From choosing stainless steel fermenters to packaging bottles and kegs, every decision shapes your future brewing business success.

What Is a Micro Brewery and How Does It Differ from Other Breweries?

A micro brewery is a small-scale brewery business designed for brewing beer in batches usually less than 30,000 barrels per year. Unlike large commercial brewing co’s focused on mass-market production, microbreweries prioritize craft beer, unique ales, and small batch quality. They use specialized micro brewery equipment like compact brewhouses, fermentation tanks, and modern wort control systems, giving brewers direct control over the brewing process and recipe development.

Key Differences Table

| Feature | Micro Brewery | Commercial Brewery | Homebrew |

|---|---|---|---|

| Batch Size | Small quantities (50–3,000 L) | Large quantities (10,000+ L) | 1–50 L |

| Brewing Goals | Craft beer, flexibility | High volume, consistency | Experimentation |

| Main Equipment | Micro brewery equipment, SS | Large tanks, automation | Home brewing kit |

| Investment | $50k–$500k+ | $500k–$10M+ | <$5,000 |

| Target Users | Small business owners, startups | Beverage companies, big chains | Home brewers, hobbyists |

Micro breweries let passionate brewers turn creative recipes into sellable products, while maintaining quality and brand identity.

“Microbreweries thrive on innovation and community, offering a personal touch that big beer brands just can’t replicate.”

Explore more on micro brewery equipment

Why Start a Micro Brewery? Market Trends and Opportunities

The global craft beer industry is booming. Consumers crave variety, unique flavors, and local stories. Starting a micro brewery puts you at the heart of this trend, whether you want to make ale, IPA, or kombucha.

Global Craft Beer Market Growth

| Year | Microbreweries Worldwide | Global Craft Beer Market (USD bn) |

|---|---|---|

| 2015 | 12,000 | $85 |

| 2020 | 22,000 | $112 |

| 2025 | 30,000+ (est.) | $150+ |

Why micro breweries are thriving:

- Control over the brewing process: Brewers can fine-tune every batch.

- Specialized brewing: Easily experiment with small-batch beer or cider.

- Closer to customers: Direct tap draft beer sales, local branding, and feedback loops.

- Low entry cost: Compared to massive brewing co setups.

Did you know? The rise of taprooms and brewpubs is driving even more demand for flexible micro brewery setups.

More on equipment: nano brewery equipment

Essential Brewery Equipment Needed for Micro Brewery Setup

Getting the right brewery equipment is the foundation of your brewing business. Here’s what you’ll need to start a brewery:

Core Micro Brewery Equipment List

- Brewhouse System: Includes mash tun, lauter tun, brew kettle, and whirlpool.

- Fermentation Tanks: Stainless steel fermenters for fermentation control.

- Hot and Cold Liquor Tanks: For temperature management.

- Wort Chiller: Rapid cooling post-boil.

- Control Panel: Modern systems (brewtech/ss brewtech) for automation.

- Packaging Line: Bottles, cans, or kegs filling machines.

- Cleaning Equipment: CIP (Clean-in-Place) systems for hygiene.

Example Table: Typical Micro Brewery Equipment Configuration

| Equipment | Main Material | Function | Typical Capacity |

|---|---|---|---|

| Mash Tun | Stainless Steel | Mashing, convert starches | 200L–2,000L |

| Brew Kettle | Stainless Steel | Boil wort, add hops | 200L–2,000L |

| Fermenter | Stainless Steel | Fermentation & maturation | 200L–2,000L |

| Bright Beer Tank | Stainless Steel | Clarify & carbonate | 200L–2,000L |

| Control Panel (Brewtech) | Steel/Plastic | Automation & monitoring | N/A |

| Bottling/Kegging System | Stainless Steel | Packaging final beer | 100–2,000 bottles/hr |

Tips for new brewery owners:

- Start with scalable brewing equipment—expand as your business grows.

- Stainless steel offers durability and easy cleaning.

- Invest in quality fermenters and control panels to ensure consistency.

Check out our full micro brewery setup solution for detailed system configurations.

Guide to Micro Brewery Design: Efficient Layouts and Best Practices

Brewery design isn’t just about looks—it’s about workflow, safety, and compliance. Whether you’re launching in a compact urban space or a suburban warehouse, a smart layout helps maximize efficiency and product quality.

Brewery Layout Best Practices:

- Linear workflow: Raw material in, packaged beer out—with no cross-traffic.

- Separation of clean/dirty zones: Avoid cross-contamination.

- Utility access: Easy connections for water, power, and drainage.

- Modular design: Plan for future expansion.

Common micro brewery design mistakes to avoid:

- Crowding equipment with no room for movement.

- Inadequate storage for brewing supplies.

- Skimping on ventilation and waste management.

“Good brewery design is as important as good beer—it saves time, reduces accidents, and makes scaling easy.”

See more example systems: small brewery equipment

Creating a Business Plan for Your Brewing Business

A solid brewery business plan is the backbone of every successful microbrewery. It’s not just for banks or investors—it’s your daily guide. Before you start a brewery, take time to plan your path to profitability.

Key components of a brewing business plan:

- Market Analysis: Who will drink your beer? What type of beer is trending in your region? Analyze local craft brewers, taprooms, and competitors.

- Product Line: Will you offer just ale and lager, or experiment with IPA, seasonal brews, or even kombucha?

- Financial Forecast: Startup costs (brewery equipment, space renovation, licenses), monthly expenses, projected sales, break-even timeline.

- Operations Plan: Team structure, supply chain, brewing schedule, packaging (bottle, keg, can), distribution.

- Marketing Strategy: Branding, tastings, digital marketing, taproom events, collaboration with local businesses.

Brewery Business Plan Table

| Section | Details & Tips |

|---|---|

| Startup Costs | Equipment, site, licenses, working capital |

| Revenue Streams | Taproom, distribution, events, merchandise |

| Risk Management | Ingredient shortages, equipment breakdown, trends |

| Scaling Plan | Adding tanks, more staff, new brewhouse location |

A detailed business plan also prepares you for investor questions, insurance, and regulatory compliance.

Step-by-Step: How to Start a Brewery from Scratch

Starting a brewery can be daunting, but here’s a proven roadmap based on real-world brewery launches:

1. Define Your Brewing Goals and Preferences

- Decide on the type of beer (ale, lager, specialty), batch size, and brewing style.

- Will you focus on tap draft beer for your local market or bottles for wider distribution?

2. Register Your Brewing Business

- Choose a legal structure, register your brand, and get the necessary brewery licenses and health permits.

3. Select a Location and Brewery Design

- Look for spaces with floor drains, high ceilings, and access for deliveries.

- Sketch a layout with separate zones for brewing, fermentation, storage, and packaging.

4. Choose and Order Micro Brewery Equipment

- Contact suppliers for mash tuns, kettles, fermenters, control panels (brewtech or ss brewtech), and a packaging system.

- Always compare quality, after-sales service, and warranties.

5. Install and Test Equipment

- Hire experienced brewers or technicians to set up, test, and calibrate your brewing system.

- Run water and cleaning cycles before your first mash.

6. Develop and Test Beer Recipes

- Use pilot batches to refine your flagship beers.

- Record every variable (yeast strain, mash temperature, hop timing, etc.) to ensure consistency.

7. Launch Your Brewery Business

- Host an opening event with tastings, brewery tours, and local media.

- Start with small quantities and build your reputation batch by batch.

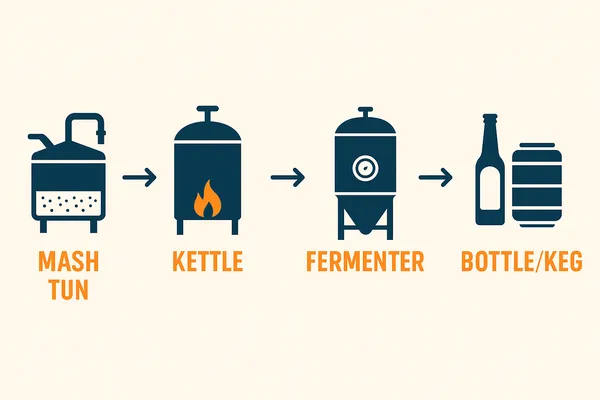

Brewing Process Explained: From Mash Tun to Bottling

Understanding the brewing process helps new brewery owners achieve great beer every time. Here’s a breakdown:

1. Mashing

- Grain is mixed with water in the mash tun to convert starches to sugars, creating wort.

- Temperature and time control are crucial for the style and body of your beer.

2. Lautering and Boiling

- The sweet wort is separated from spent grains and transferred to a brew kettle.

- Hops are added and the wort is boiled to sterilize and extract flavor.

3. Cooling and Fermentation

- Hot wort is rapidly cooled in a wort chiller and pumped into a fermenter.

- Yeast is added; fermentation begins, producing alcohol and flavor.

4. Conditioning and Packaging

- Beer matures in the fermenter or a bright tank.

- It’s clarified, carbonated, and packaged into bottles, kegs, or cans.

Quick Fact: A typical ale takes 2–4 weeks from mash to bottle. Some lagers or specialty brews may require longer fermentation and maturation.

Want to dive deeper? Explore beer fermenter options for every batch size.

Case Study: Small Brewery Success Story

Background:

Sara, a passionate home brewer, wanted to start brewing commercially. She invested in a 500L micro brewery setup with stainless steel fermenters, a brewtech control system, and a small taproom.

Process:

- Developed a clear business plan with help from local craft brewers.

- Chose scalable micro brewery equipment for flexibility and future expansion.

- Focused on local ingredients and small-batch experimentation.

- Used social media to promote launch events and limited-edition ales.

Results:

- Broke even in 18 months, expanded product range to kombucha and cider.

- Won local craft beer awards, secured distribution deals with restaurants.

“By focusing on quality, community, and continuous learning, Sara’s microbrewery became a regional favorite—proof that with the right plan and equipment, new brewery owners can succeed.”

Small Brewing Systems vs. Large-Scale Brewing Equipment

Small-scale brewing is all about flexibility, control, and unique products. But how does it compare to traditional large breweries?

Comparison Table

| Factor | Small Brewing (Microbrewery) | Large-Scale Brewing |

|---|---|---|

| Control | Full control over brewing process | More automated, less flexible |

| Batches of Beer | Small, experimental | Consistent, large volumes |

| Investment | $50k–$500k+ | $500k–$10M+ |

| Brewing Needs | Craft, niche, local market | Mass market, export |

| Market for Beer | Local, taprooms, small chains | National/international |

| Equipment Needed | Mash tun, kettle, fermenters, etc. | Larger tanks, automated lines |

Why small breweries thrive:

- Experiment with new recipes quickly

- Lower financial risk

- Closer customer relationships

For more, see nano brewery system and micro brewery equipment.

FAQs: Micro Brewery Setup and Brewing Business

What’s the difference between a microbrewery, a nanobrewery, and a home brewery?

A microbrewery brews small but commercial quantities of beer, usually 3,000–30,000 barrels/year, serving local markets or taprooms. Nanobreweries operate on an even smaller scale (often under 5 barrels per batch), perfect for startups or experimental brewing. A home brewery is for personal use, with minimal equipment and no commercial sales.

What type of brewing equipment do I need to start a brewery?

You’ll need a mash tun, lauter tun, brew kettle, hot/cold liquor tanks, wort chiller, stainless steel fermenters, control panel (such as ss brewtech), a packaging solution (bottle, keg, or can filling), and a CIP cleaning system. Start with a scalable brewing system and add more pieces of equipment as your business grows.

What’s the average cost to set up a microbrewery?

Expect to invest anywhere from $50,000 to $500,000+ depending on location, brewing system capacity, quality of equipment, and fit-out. This includes brewery equipment, facility renovation, licenses, and initial working capital for brewing supplies and staff.

Do I need a business plan to start brewing commercially?

Absolutely. A solid brewery business plan outlines your brewing goals, market analysis, financials, and operations. It’s also crucial for attracting investors or securing financing.

Can I make kombucha, cider, or spirits with micro brewery equipment?

Yes, many micro breweries use the same tanks and fermenters for beer, cider, or kombucha. With the right cleaning and fermentation control, you can diversify your beverage lineup.

What licenses or permits are needed for a brewing business?

You’ll need a federal brewing permit (TTB in the US), local state/city alcohol licenses, and health/safety certifications. Always check your country’s regulations before you start brewing commercially.

What’s the best way to scale a small brewing business?

Begin with a scalable micro brewery setup—modular tanks, flexible brewhouse layout, and a control system that grows with you. Reinvest profits, expand taproom sales, and explore distribution partnerships as demand increases.

Industry Trends and Future Opportunities

The brewing industry is evolving. Consumers demand authenticity, variety, and sustainable practices. Here’s how micro breweries can lead:

- Sustainability:

Use energy-efficient brewing equipment, local ingredients, and eco-friendly packaging. Many small brewing businesses now recycle water and use renewable energy. - New Beer Styles:

Specialized brewing for low-alcohol beers, hard seltzers, and hybrid beverages like kombucha or CBD-infused ales is booming. - Direct-to-Consumer Sales:

More breweries are opening taprooms, selling online, and offering experiences like brewing courses and guided tastings. - Smart Brewing Technology:

Brewtech systems and IoT controls allow precise monitoring of fermentation, temperature, and quality for even small-scale brewing.

Key Brewing Terms Explained

- Mash Tun:

A vessel where crushed grain (malt) is mixed with water and heated, starting the conversion of starches to sugars. - Fermenter:

A stainless steel tank where yeast is added to the wort, and fermentation produces alcohol and flavor. - Wort:

The sweet liquid extracted from the mashing process—becomes beer after fermentation. - SS Brewtech:

A respected brand for stainless steel brewery equipment, often used as a synonym for modern, modular brewing kit. - Bright Beer Tank:

Tank used for final conditioning and carbonation before bottling or kegging. - Tap Draft Beer:

Beer served directly from a keg or tank, typically fresher and often the flagship product of many microbreweries.

Common Mistakes New Brewery Owners Should Avoid

- Underestimating startup costs:

Factor in renovation, hidden fees, staff training, and a buffer for unexpected delays. - Skipping a business plan:

Even small breweries need clear financial and market strategies. - Neglecting quality control:

A great batch of beer needs consistency. Invest in lab equipment and keep detailed brewing records. - Overlooking regulatory compliance:

From alcohol permits to health codes, every region has unique requirements.

Best Practices for New Brewers and Microbrewery Startups

- Network with other craft brewers and local associations.

- Pilot small batches before scaling recipes.

- Prioritize safety—both for staff and customers.

- Engage your community: Offer brewery tours, brewing courses, or launch events.

- Continuously learn: Brewing is part science, part art. Stay updated with new trends, technologies, and brewing needs.

Internal Links & Further Reading

- See complete micro brewery setup solutions for every budget.

- Discover nano brewery equipment for sale for super-small batches and startups.

- Browse beer fermenter options for every style and size.

- Learn about kombucha brewing equipment.

- Explore advanced craft beer brewing equipment and expand your lineup.

- Get inspiration for a microbrewery business plan.

Summary: Key Takeaways for a Successful Micro Brewery Setup

- Micro breweries offer creativity, flexibility, and direct connection with customers.

- A well-structured business plan, efficient brewery design, and scalable brewing equipment are essential.

- Don’t skip key steps: market analysis, proper licensing, and quality control.

- Start small, experiment, and use feedback to guide your brewing business growth.

- Leverage smart brewing systems and stainless steel fermenters for consistent, high-quality beer.

- Engage your local community and stay ahead of industry trends.

- Use professional resources and turnkey solutions to get your brewery off the ground faster and smarter.

Ready to brew your dream?

Explore scalable micro brewery solutions and start your brewing business journey today!