Why choose Micet to supply your distillery equipment?

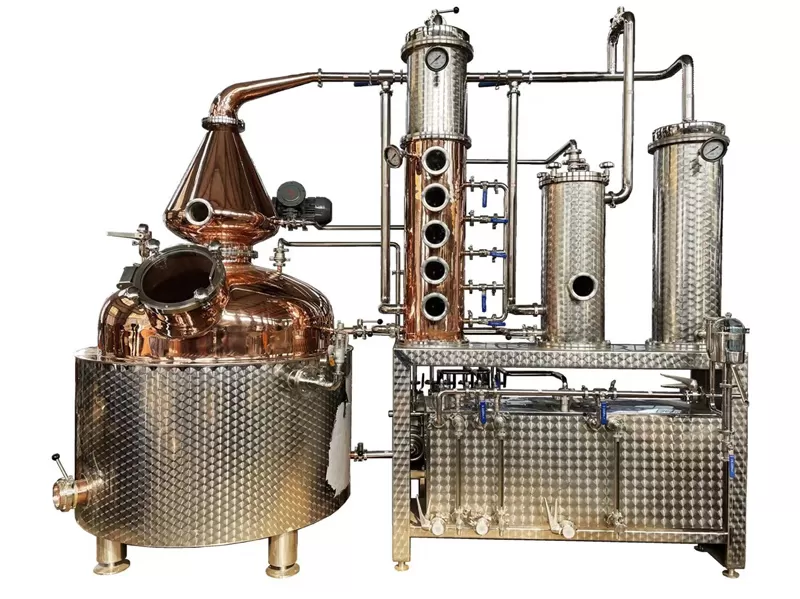

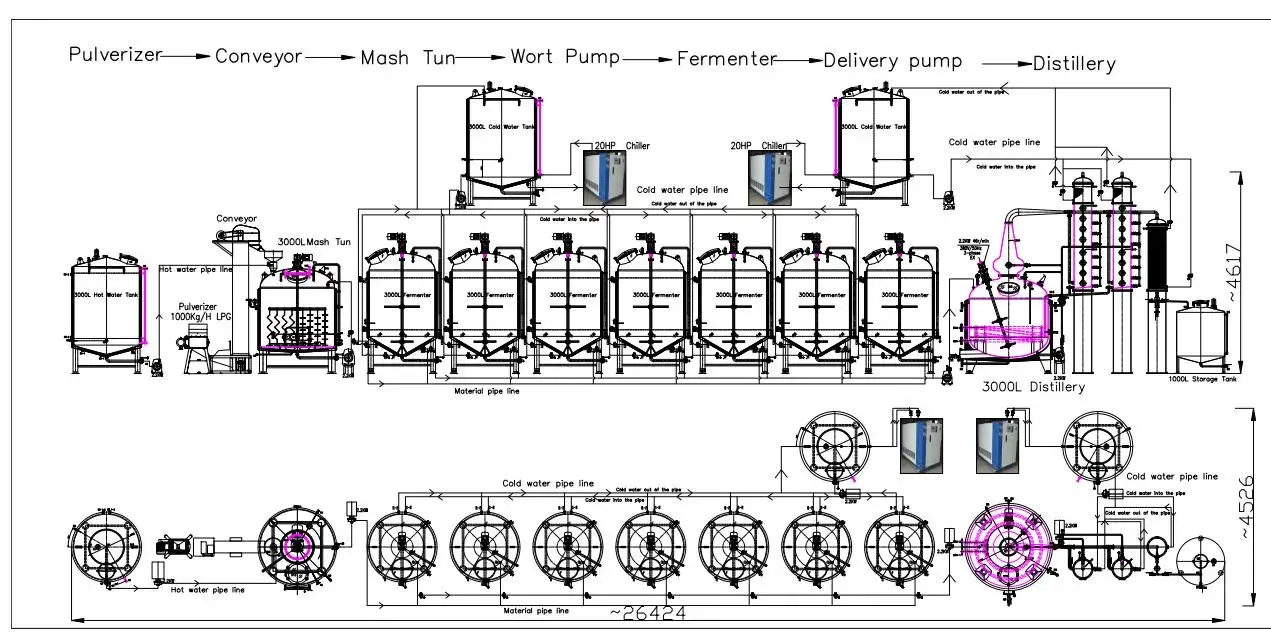

1. Turnkey Solution Purchase

Whether your budget for your craft distillery equipment is $5,000.00 or $500,000.00 we can set you up with a complete distilling solution, from mashing, fermenting to distilling and storing, as well as the auxiliary machines.

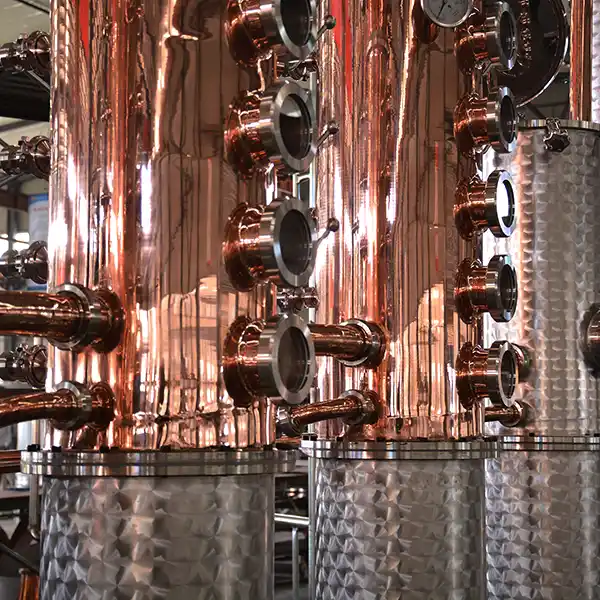

2. High-grade Copper Material

All of our copper vessels are manufactured with high quality TP2 materials, are of the best quality of copper.

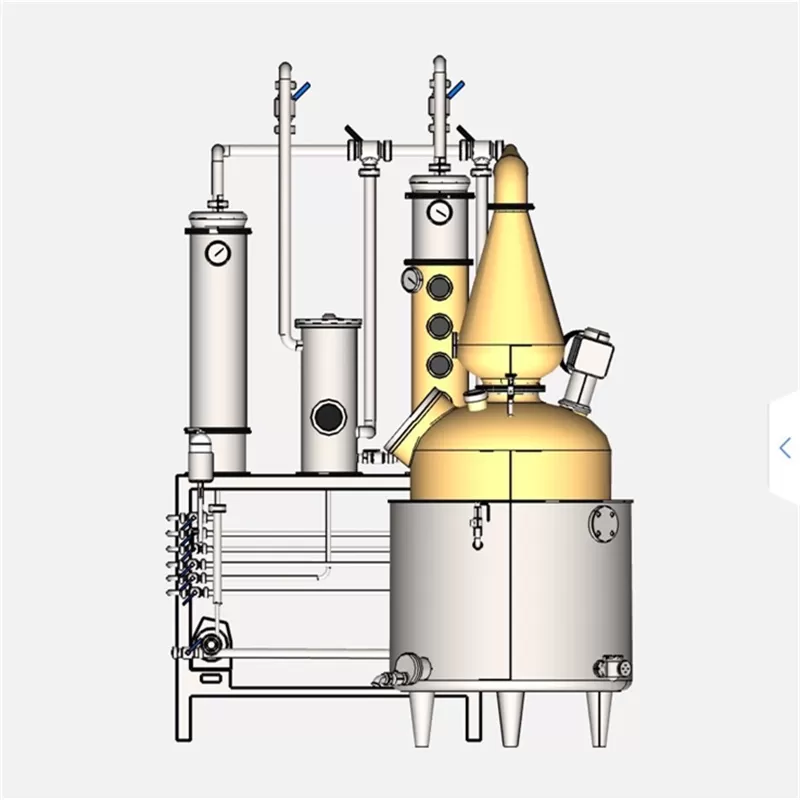

3. Copper Head Welding Process

The quick-installation and copper welding methods are one-time over-welding to ensure that the parts in contact with the alcohol are made of copper, which is beautiful and generous; the sealing performance is due to the pressure resistance of the sealing ring, without the influence of welding parts, thus improving the service life of the equipment.

4. Manhole Craftsmanship

The manhole is made of red copper, and it is welded with the stainless steel flange to ensure that the parts in contact with the alcohol are made of copper, with strong sealing performance and long service life.

5. Distillery Tower Process

The parts in contact with the alcohol are made of red copper, and the design process of tumbling is adopted.