1. Automation level can be selected

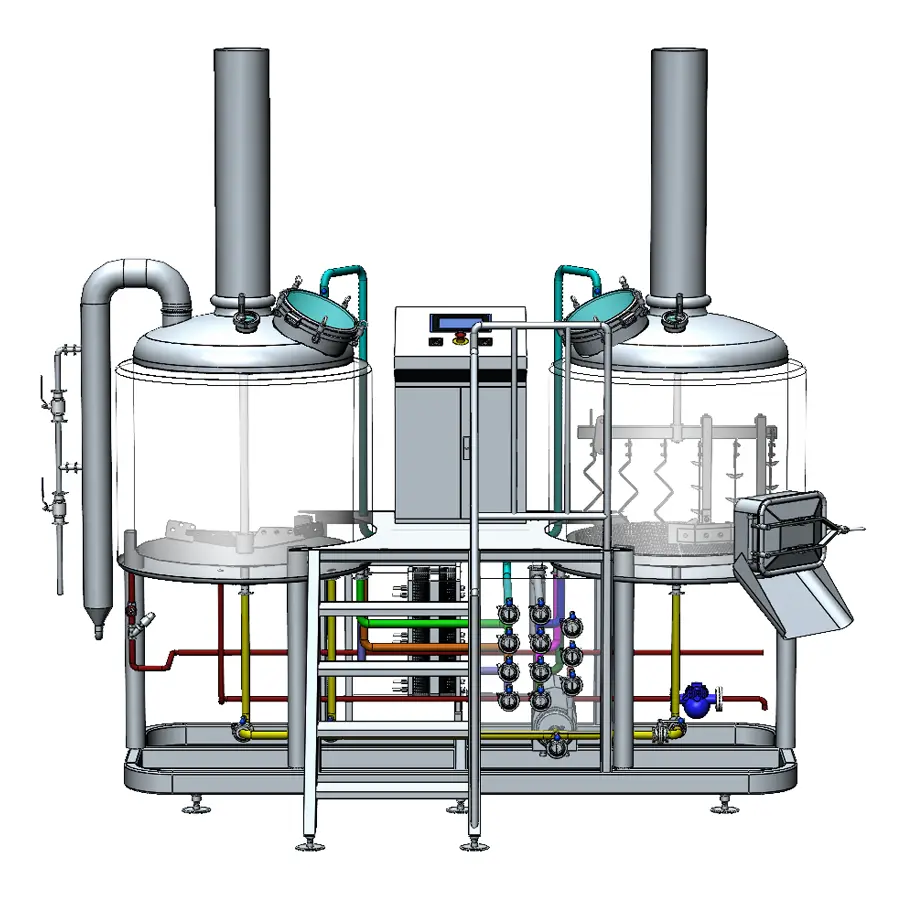

Each equipment is equipped with the reasonable collocation and process connection, and reasonable automation (although the automation can be infinitely improved, it is recommended that each customer choose the degree of automation according to their own conditions, such as the most core and The important production process is fully automated, and the auxiliary labor intensity is not high, and manual assistance is also a good choice).

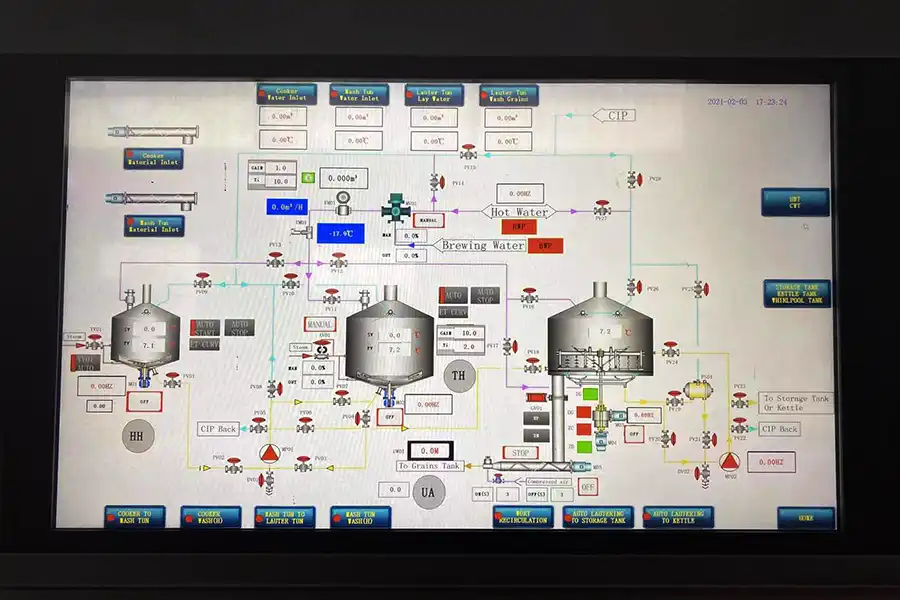

2. Visualization of brewing recipes and automatic brewing procedures

This process can set brewing formula parameters, controls the feeding process, and will automatically adjust the water temperature, water speed, etc., so as to better mix the material and water; when the process is over, stop the relevant actuators, and there will be related sensors and inverters to protect the process.

3. Segmented leaching brewing

Most brewers hope to achieve segmented leaching brewing, but for small equipment, saccharification and filtration are mostly integrated. Due to the existence of rake knives, electric heating pipes cannot be installed. Therefore, if you want to achieve staged brewing, steam heating is the most commonly used method.

4. Save labor while maintaining stable beer quality

It can realize the production of any beer types and is easy to operate, as long as there are formulas and process parameters, which solves the problem that high-end brewers are hard to find, and also solves the problem of high labor costs in the production process.).

5. Easy for brewery expansion

With high scalability, the brewhouse equipment pipeline and control system constitute the core of efficient and high-quality production, and the power system provides sufficient supply. In the future, the production capacity can be expanded only by increasing the number of fermentation tanks.

6. Off-site monitoring and remote access

With the site manager installed on your phone, no need for on-site monitoring during the fermentation process, we can use the mobile phone to remotely monitor and understand the progress of fermentation in real-time.

In this case, the brewer’s time is greatly liberated. When you are out, you can open your mobile phone and check the real-time situation of your fermenters.