Commercial brewery systems refer to the end-to-end equipment and processes used for beer production at an industrial scale. Setting up a commercial brewery requires significant investments in tanks, piping, controls, cleaning systems, and more based on the targeted output volume and beer styles.

This equipment guide covers key components in a commercial brewery system for medium to large scale craft breweries producing anywhere from 5,000 to over 500,000 barrels annually. We discuss popular equipment types, sizing considerations, design standards, pricing, suppliers, installation factors, operation, maintenance and more across the production workflow – brew house, fermentation, cellars, packaging, and cleaning systems.

Brewing Equipment Types and Characteristics

| Equipment |

Description |

Key Characteristics |

| Mash Tun |

Mixes milled malt/grains with hot water to extract sugars and convert starches into fermentable sugars. |

Size – impacts number of batches per day. Material – stainless steel or copper. |

| Lauter Tun |

Separates sweet wort from grains after mashing. |

Number of valves and sparging method impact efficiency. |

| Brew Kettle |

Boils sweet wort with hops for flavor, aroma, preservation. |

Size affects batch volume. Direct or indirect heat. Number of ports. |

| Whirlpool |

Settles out solid particles from boiled wort using centrifugal force. |

Placement – attached to kettle or standalone. Conical shape for trub separation. |

| Wort Chiller |

Quickly cools hot wort after the boil to prepare for fermentation. |

Plate or shell and tube heat exchanger. Cooling capacity. |

| Fermentation Tanks |

Yeast converts sugars into alcohol and CO2 during primary fermentation. |

Material – stainless steel or plastic. Size, number – dictate batch sizes and total output. Temperature control. |

| Brite Tanks |

Clarifies and carbonates beer after fermentation, before packaging. |

Number, size options. Pressure rating for carbonation. Temperature control, CIP. |

| Filter |

Removes haze particles for clear finishes |

DEP, plate and frame, centrifugal. Filtration level – coarse to sterile. Fully automated. |

| Bottler/Canner |

Fills packaged product into bottles, cans, kegs. |

Inline or rotary fillers. Speed, size, packaging type options. Date coder, labeling. |

| Piping |

Interconnects all processes in brewery. |

Sizes – inlet, outlet, transfers, CIP. Slope for drainage. High purity stainless, aseptic glass. |

| Steam System |

Generates steam to power processes, heat water, sanitize. |

Fuel type – natural gas, biomass. Redundancy. Water quality protection. |

| Cooling System |

Maintains fermentation temp for lagers, brite tanks. |

Glycol, ammonia, CO2. Pumping stations. Controls integration. |

| CO2 Recovery |

Captures CO2 from fermentation tanks. |

Purification system. Buffer tanks. Sensor-based automation. |

| Clean-in-Place |

Automated cleaning of tanks, lines without disassembly. |

Spray balls, pumps, chemical tanks, valves, controllers. Recovers cleaning solutions. |

| Process Control |

Automates temp, pH, DO, flow parameters. |

Touchscreens, sensors, valves, analytics software. Remote monitoring. |

Brewery Equipment Selection Considerations

Selecting brewing system equipment depends on business goals for production scale, beer types, product quality targets, degree of automation, and budget. Key factors influencing equipment sizing and configurations:

Production Volume

Matching equipment capacity to monthly, yearly volume targets is key. Standard barrel (bbl) is unit of measurement. Consider peak demand, seasonality, growth plans.

Beer Varieties

Equipment must suit brewing process needs – shorter mashes for pilsners, custom boiling for IPAs etc. Flexibility allows producing ales, lagers, specialty beers.

Degree of Automation

More automated systems have higher upfront costs but save long term labor. Consider pros/cons of manual vs automated options.

Quality Targets

Achieving flavor consistency, extending shelf life, managing dissolved oxygen, and eliminating contaminants impact equipment selections like filtration, cleaning systems etc.

Physical Space & Layout

Available production floorspace, ceiling height, doorway access, loading bays, construction support etc. influence equipment sizes configurations.

Budget Availability

Buying all equipment upfront lowers incremental costs but requires large capital expenses. Consider pacing investments across critical functionality first.

Commercial Brewing System Design Standards

Adhering to design and construction standards ensures the brewing equipment reliably meets safety, integrity and quality needs through its operational lifetime spanning decades.

| Standard |

What It Covers |

How It Helps |

| ASME BPE |

Brewery process equipment design, fabrication, inspection, testing |

Ensures integrity safety for pressure vessels, internal structures |

| ANSI/3A Sanitary Standards |

Hygienic equipment finish, cleanability, aseptic eligibility |

Prevents contamination and associated recalls |

| International Building Code |

Construction, electrical, ventilation, plumbing, safety |

Assures facility and infrastructure integrity, personnel safety |

| ASTM Material Standards |

minimum allowable strengths for stainless steel alloys used |

Reduces corrosion and rust preventing product defects |

| UL 508A Control Panel |

Industrial control panels, sensing, alarming |

Robust automation and monitoring |

| IEEE 802.3 Ethernet |

Local Area Networks, TCP/IP communications |

Secure data transfer for monitoring, operations |

Additionally following GMP methodology in equipment maintenance, calibration, operations and integrating detailed standard operating procedures in training programs help meet quality goals.

Applications of Commercial Brewing Systems

Commercial brewing systems see usage in standard beer production in brew pubs, microbreweries, regional craft brewers and nationally distributed big beer brands:

| User |

Typical Production Volume |

Popular Equipment Choices |

| Brewpub / Microbrewery |

500 to 5,000 barrels annually |

3-vessel direct fire brew house, simple fermentation, brite tanks, manual bottling line |

| Regional/Craft Brewer |

5,000 to 30,000 barrels annually |

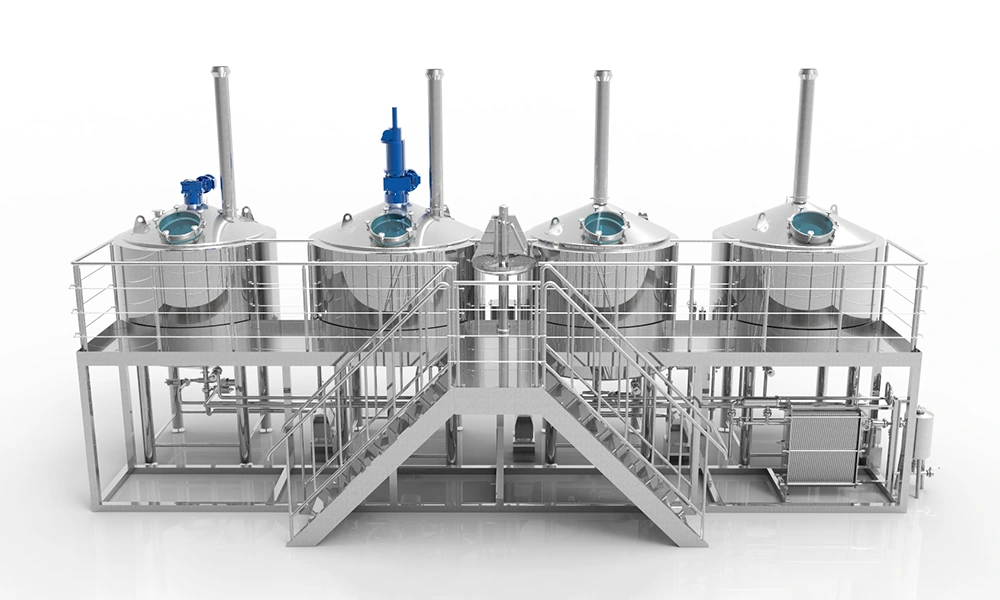

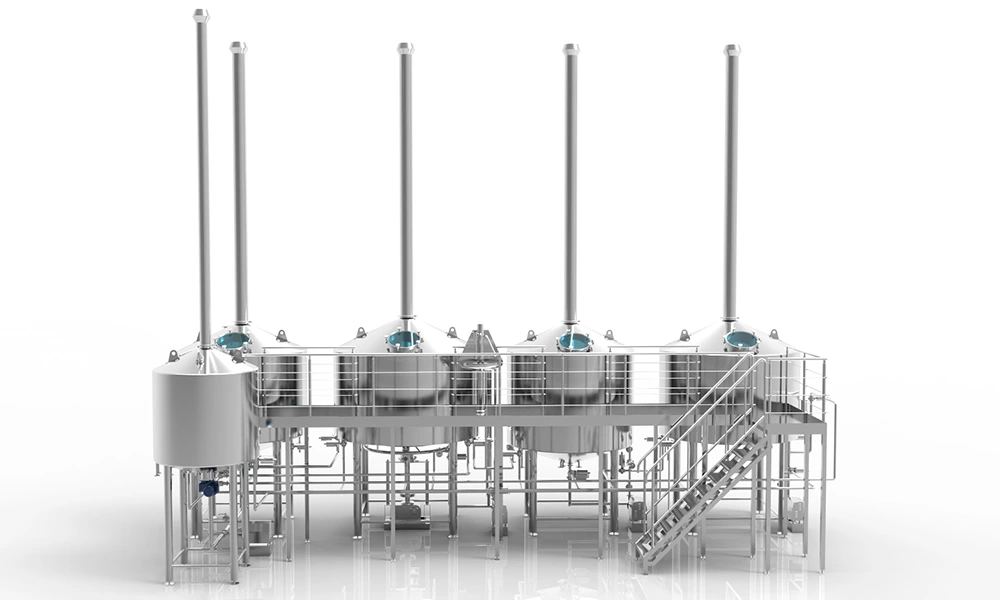

4-vessel steam brew house, glycol cooling, automatic filtration, canning line |

| Expanded Regional Brewer |

30,000 to 200,000 barrels annually |

Multi-vessel automated brew house, robotic packaging, ERP/MRP software, CO2 capture |

| Large Brewer/Contract Facility |

over 200,000 barrels annually |

Highly automated industrial scale continuous brewing, membrane filtration, bottle fillers |

The same equipment types see some specialized usage scenarios:

Contract / Toll Brewing: Larger breweries rent their excess capacity for small brewers to test recipes, enter new markets. Flexibility is key.

Innovation Breweries: Pilot experimental small batch recipes with custom mashing, hopping, fermentation profiles before scaling up.

Teaching Breweries: University programs training future brewmasters. Education-oriented flexibility trumps high volume.

Quality Testing Labs: Ensure uniformity and stability for commercial production. Fully automated, sterile sample handling is critical.

Specifications of Commercial Brewing Systems

Below are typical specification ranges across key commercial brewing equipment. Consult with experienced brewery design consultants for sizing suited to your specific production goals.

| Equipment |

Typical Sizes Available |

Material Standards |

Design Factors |

| Brew Kettle |

5 to 100 barrel batches |

ASME SA-240 S31603 stainless |

Height/Diameter ratio, heating method, 1.5x peak batch capacity |

| Mash Tun |

5 to 200 barrel batches |

Internal rakes, ASME SA-240 S31603 stainless |

Depth for mash viscosity, wall/floor angles, number of inlets/outlets |

| Fermenter |

0.5 to 300 barrel unianks |

ASME SA-240 S31603 stainless, electrolytic polish |

Height/Diameter ratio, cooling method, conical vs. cylinder |

| Brite Tank |

5 to 150 barrel capacity |

ASME SA-240 S31603 stainless |

ASME pressure rating for carbonation, removable top/bottom heads, sanitary fittings |

| Filter |

Depends on batch sizes |

All stainless contact parts |

Filtration stages, automation interface, clean-in-place |

| Filler |

40 to 140 cans/minute, 250 to 2000 bottles/hr |

304 stainless frames, tool steel guides |

Speed vs change over time trade offs, sanitation compliance |

| Chiller |

Match to max kettle size+20% |

ASME shells, TEMA standards for exchangers |

Peak cooling loads, total fermentation demand, safety factors |

Height restrictions, door access widths, floor capacity etc imposeconstraints when selecting equipment dimensions.

Cooling load is the biggest driver of system capacity and peak demand based on tank and line heat loads and intermittent usage patterns.

Safe to use

All the construction material of our brewing vessels used are SUS304 high quality food grade materials, which are certified by the SGS company.

Performance

Our commercial beer brewing equipment has separate GFCI breakers. On the rare chance that an element fails, your panel will still function, and your brew session can continue.

Easy to Clean

Our commercial brewing systems have sanitary construction with food grade valves, sanitary welds and tri-clamp fittings. Spend less time cleaning, and more time brewing delicious brews.

Long-term Durability

Our beer brewing systems are engineered to commercial standards and are built to last years of brewing.

Wort Protection

With our Ultra-Low watt density elements, plus our ability to lower the element’s power (which makes the watt density proportionally lower), there is no scorching or off-flavours.

Low Cost Steam Vent

With our commercial brew kettles, use condensate stack or steam condenser to vent the steam. Steam MUST be properly ventilated to avoid serious mould and potential health safety issues in your building.