Why Your Cider Making Equipment Choices Matter

Do you find yourself frustrated with low juice yields? Are you tired of inconsistent cider quality that customers reject? Maybe you’re overwhelmed by the growing demand for premium ciders but lack the right tools to scale up.

These are not just minor issues. They can mean the difference between profit and loss in today’s competitive craft beverage market.

When you see other cider makers achieving premium prices while your product struggles to stand out, it’s not just bad luck. Equipment limitations are often the hidden bottleneck holding back your cider business from reaching its full potential.

Fortunately, the right equipment solution exists for every cider maker, from backyard hobbyists to commercial producers. With the cider market projected to reach USD 6.94 billion by 2032 (growing at 3.34% annually), now is the perfect time to make smart equipment choices.

Let’s explore everything you need to know about cider making equipment to transform your operation.

What is Cider Making Equipment?

Cider making equipment includes all the tools needed to turn fresh apples into delicious cider. The basic process has three main steps:

- Crushing – breaking down apples into small pieces

- Pressing – extracting juice from crushed apples

- Fermentation – turning sweet juice into cider

Core Components You Need

Apple Crushers/Fruit Mills

- Grind apples into pulp called “pomace”

- Come in manual and electric versions

- Affect juice yield significantly

Press Types

- Hydraulic press – uses fluid pressure for high extraction

- Rack-and-cloth press – traditional method with cloth layers

- Bladder press – uses inflatable membrane for gentle pressing

Fermentation Tanks

- Stainless steel – durable, easy to clean, temperature control

- Plastic – more affordable but less durable

- Must maintain stable temperatures for proper fermentation

“Getting the right equipment can mean the difference between 50% and 75% juice yield from the same apples,” explains Nancy Chen, who has 15 years of experience helping cideries optimize their production. “That’s a 25% revenue increase without buying more fruit.”

Essential Equipment for Beginners

If you’re just starting out, don’t let equipment costs discourage you. Many beginners find success with affordable starter kits.

Starter Kits Under $500

| Equipment Bundle | Features | Price Range |

|---|---|---|

| Basic Manual Press + Crusher | 3-gallon capacity, wooden construction | $250-350 |

| Electric Crusher + Small Bladder Press | 5-gallon capacity, partial automation | $400-500 |

| Vigo Hydraulic Press Combo | 7-gallon capacity, higher juice yield | $450-500 |

Must-Have Tools for Any Setup

- Hydrometers for measuring sugar content

- Bottling and capping systems for final packaging

- Sanitizers to prevent contamination

- Fermentation locks to allow gas escape while blocking contaminants

“Starting small doesn’t mean sacrificing quality,” says a production director with 13 years of experience. “Most craft cider makers begin with modest equipment and upgrade as they grow. The key is choosing equipment that can deliver consistent results at your current scale.”

For those ready to move beyond basic setups, the 1000L Small Batch Brewing Systems offer an excellent balance of production capacity and quality control for growing cider operations.

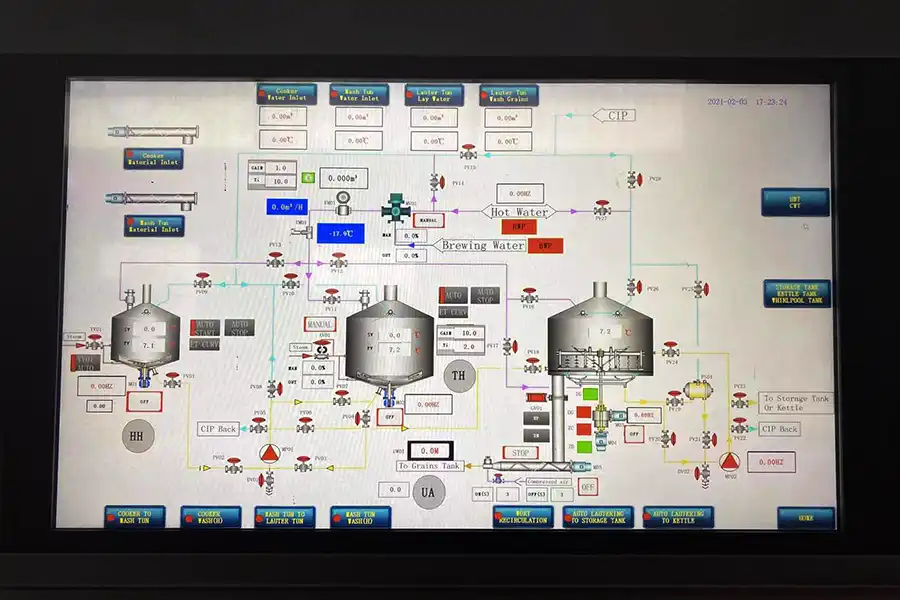

Advanced Commercial Equipment

As demand for your cider grows, manual processes become bottlenecks. Modern commercial equipment solves this problem.

Industrial-Scale Solutions ($5,000+ Range)

- Electric fruit conveyors – automate apple handling

- Pasteurization units – extend shelf life

- Automated bottling lines – increase packaging speed

Commercial producers should consider throughput per hour and juice recovery rates when evaluating equipment. Modern systems can achieve up to 22% higher juice yields than traditional methods, according to market data.

For medium-sized operations looking for professional-grade fermentation solutions, Stainless Steel Fermentation Tank & Bright Tanks provide the temperature control and sanitation features needed for premium cider production.

Top 10 Cider Presses Compared

Comparison Table: Capacity/Material/Price

| Press Model | Capacity | Material | Price Range | Key Feature |

|---|---|---|---|---|

| Speidel Hydro 40L | 40 liters | Stainless steel | $1,200-1,500 | Bladder technology |

| Crossbeam Wooden | 25 liters | Oak wood | $600-900 | Traditional design |

| Grifo Marco SS | 50 liters | 304 stainless | $2,000-2,500 | Fast operation |

| Vigo 18L Hydraulic | 18 liters | Steel/wood | $400-600 | Good for beginners |

| Lancman VSPX160 | 160 liters | Steel | $3,500-4,000 | Commercial grade |

| Happy Valley Manual | 16 liters | Cast iron | $250-350 | Budget-friendly |

| Weston Fruit Press | 12 liters | Steel/wood | $300-450 | Compact design |

| Jaffrey Rack-Cloth | 20 liters | Hardwood | $800-1,000 | Traditional method |

| MacIntosh Bladder | 75 liters | Steel | $2,200-2,600 | Gentle pressing |

| Hydraulic Basket | 90 liters | Stainless steel | $2,800-3,200 | High extraction |

User Reported Pros and Cons

Users consistently report that hydraulic presses offer the best balance of juice yield and price for mid-sized operations. Bladder presses receive high marks for juice clarity but come at a higher price point.

“We tested three different press types before settling on our current system,” shares a quality inspector with 11 years in the field. “The right press depends on your cider style goals, batch size, and budget constraints.”

For those looking to upgrade to a complete brewing system with integrated pressing capabilities, the 2000L 3 Vessel Microbrewery Equipment offers comprehensive solutions for serious cider producers.

Maintenance & Troubleshooting

Cleaning Protocols for Fermentation Tanks

- Rinse with warm water

- Apply food-grade sanitizer

- Scrub all surfaces

- Rinse thoroughly

- Air dry or wipe with clean cloth

Common Issues and Fixes

Low Juice Yield

- Problem: Getting less juice than expected

- Fix: Adjust grinder calibration for finer pomace

Cloudy Cider

- Problem: Cider won’t clear properly

- Fix: Use pectic enzyme and proper filtering methods

Slow Fermentation

- Problem: Fermentation takes too long

- Fix: Check temperature control and yeast health

“Preventative maintenance saves thousands in emergency repairs,” explains a service team member with 22 years of experience. “Simple daily cleaning routines can extend equipment life by 5-7 years.”

Latest Innovations (2025 Trends)

The cider equipment industry continues to evolve with exciting new technologies:

AI-Powered Fermentation Monitors

These smart devices track:

- Sugar conversion rates

- Temperature fluctuations

- Potential contamination

- Optimal bottling times

Market data shows these systems reduce production errors by an impressive 40%.

Eco-Friendly Pomace Compost Systems

- Turn waste into useful garden products

- Reduce disposal costs

- Create additional revenue streams

Portable Nano-Brewery Kits

Perfect for small-batch experimentation, these compact systems help craft producers test new flavor profiles before scaling up production.

“Innovation drives quality improvement,” says Nancy, who oversees global operations across 12 service centers. “The most successful cider makers embrace new technology while respecting traditional methods.”

Regional Market Share

The global demand for cider equipment varies by region:

- Europe: 42% (UK and France lead)

- North America: 33% (US craft cideries dominate)

- Asia-Pacific: 18% (Growing rapidly in India/China)

- Other regions: 7%

This regional diversity brings unique equipment needs, with European producers often preferring traditional methods while North American craft makers adopt more technological innovations.

Equipment Innovation Insights

| Technology | Adoption Rate | Impact |

|---|---|---|

| AI Fermentation Controllers | 28% | 40% reduction in production errors |

| Hydraulic Press Upgrades | 61% | 18-22% boost in juice yield |

| Nano-Brewery Kits | $1.2M in sales | 37% growth since 2022 |

These innovations aren’t just for large producers. Small and mid-sized cideries can benefit from targeted investments in key technologies.

Global Cider Market Trends

Global Market Growth (2023-2032)

Regional Market Share (2024)

Key Equipment Trends

- → AI Fermentation: 28% adoption

- → Hydraulic Presses: 61% use

- → Nano-Brew Kits: +37% sales

- → Eco Systems: 73% in EU

FAQs About Cider Making Equipment

“Can I use a wine press for cider?”

Yes, but there are important differences. Wine presses are designed for grapes, which release juice more easily than apples. For best results:

- Use a dedicated apple crusher first

- Expect longer pressing times

- Consider apple-specific press cloths

“How much equipment space do I need?”

For small production (up to 100 gallons):

- Minimum 100 square feet

- 8-foot ceilings

- Good ventilation

For commercial production:

- 500+ square feet

- Floor drains

- Separate fermentation room

“What materials are best for cider equipment?”

For food contact surfaces:

- 304 stainless steel (standard)

- 316 stainless steel (premium, more corrosion-resistant)

- Food-grade HDPE plastic (budget option)

“Equipment material choice affects not just durability but also flavor development,” advises a production specialist who understands how seemingly small details impact final quality.

Making the Right Equipment Investment

When selecting cider making equipment, consider these factors:

- Current production volume

- Growth plans for next 3-5 years

- Available space and utilities

- Budget constraints

- Target cider styles

“The best equipment solution matches your specific needs rather than following industry trends,” explains a senior engineer with experience designing custom solutions for cideries of all sizes.

For operations ready to scale up, the 20HL 4 Vessels Commercial Brewery Equipment provides comprehensive capabilities for serious commercial cider production.

Conclusion: Elevating Your Cider Production

The global cider market continues to grow, with premium products leading the way. Equipment choices directly impact your ability to meet this demand with quality products.

Whether you’re just starting out or looking to expand an established operation, remember that equipment is an investment in your cider’s quality and your business’s future.

By selecting the right tools for your specific needs and maintaining them properly, you can overcome common production challenges and create consistent, high-quality cider that stands out in today’s competitive marketplace.