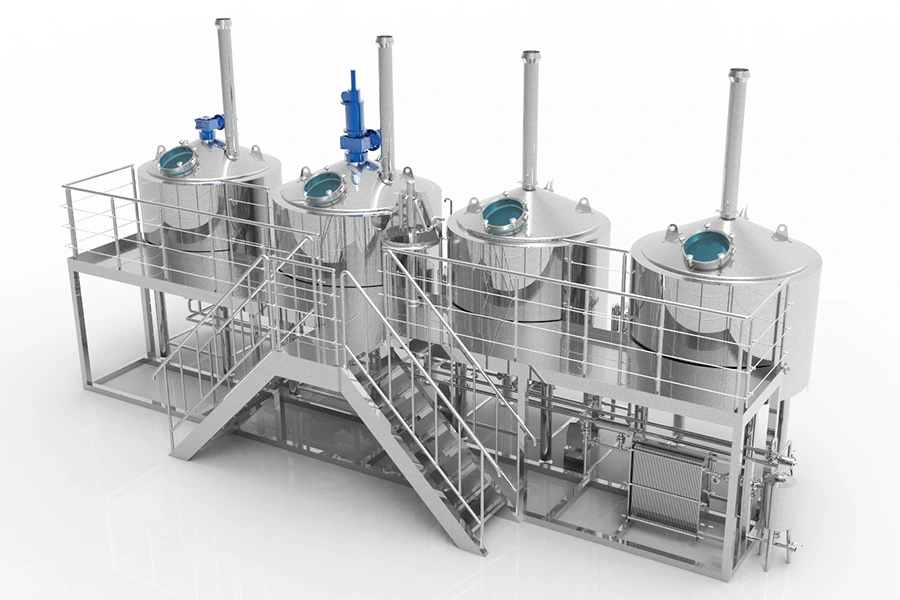

Q: What are the most critical first investments I should focus on for my new brewery?

A: Start with foundational gear allowing end-to-end beer production at smallest viable scale – brewhouse, fermentation tanks, refrigeration and cleaning/sanitation capabilities. Delay high cost packaging, QC labs, automation upgrades until revenue from first sales allows further investments.

Q: Should I buy imported Chinese equipment to save on costs?

A: Evaluate duty, shipping, installation support, warranty coverage, replacement parts supply chain and metals quality before deciding. For critical equipment like fermenters focus first on reliability over cost.

Q: Our brewery needs more fermentation capacity – should we get more tanks or replace existing ones with larger size options?

A: Carefully evaluate options based on available space, peak demand scenarios, production scheduling flexibility needs and orçamento disponível. Blending additional uni-tanks optimizes sizing across ales, lagers, specialty beers better than one giant tank.

Q: We plan to start canning – should we buy a manual filler or automatic rotary inline system?

A: Automatic rotary systems allow faster fill rates and minimize oxygen pickup achieving longer shelf life for retail distribution. But manual fillers allow flexible four pack and crowler packaging capabilities. Evaluate product customization and packaging diversity needs.

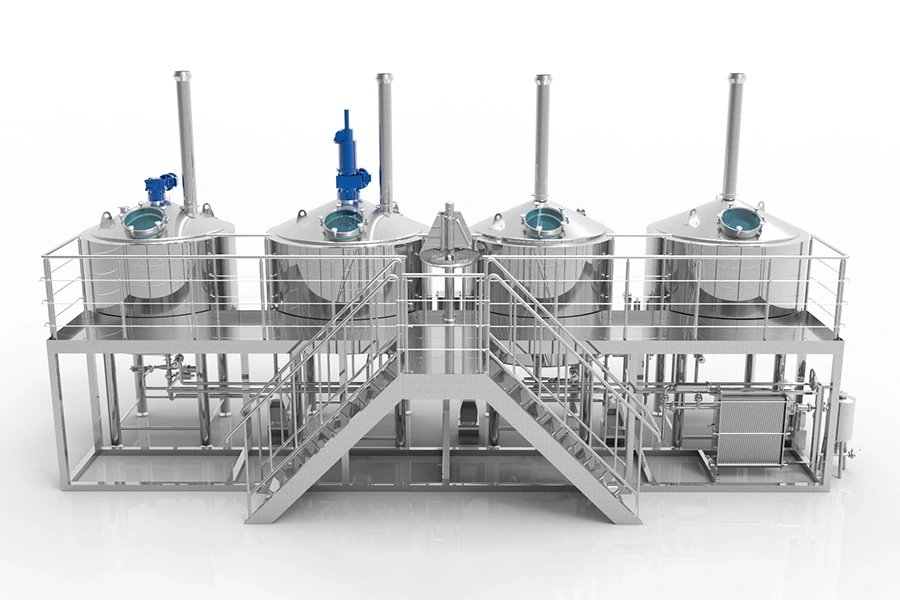

Q: How often should I get my brewing equipment inspected?

A: Establish routine inspection checklists internally but bring third party experts annually to audit safety mechanisms, electrical grounding, tank seals, automation controls, replacing end-of-life components to prevent operational failures or contamination risks.