The steps and ingredients used by home brewers and professional brewers alike are the same. Home brewing equipment and commercial brewery equipment are designed for different production scales and have different features and functions. Read today’s blog and you’ll learn that there are many similarities and differences between home brewing and commercial brewing.

Different definitions

What is home brewing?

Homebrewing refers to small-scale brewing enthusiasts who brew beer, mead, or cider at home. They usually brew beer at home as a hobby and do not sell it to others.

What is commercial brewing?

Commercial brewing is when a business or brewery brews beer or other types of alcohol. Commercial winemakers sell the brewed wine to consumers or wholesalers for profit.

Production scale is different

For the most part, the brewing process is the same for both commercial and home brewing: grains are mashed, hops added, wort fermented, beer aged, and finally bottled. The biggest difference is that commercial breweries can produce more beer than home brewing.

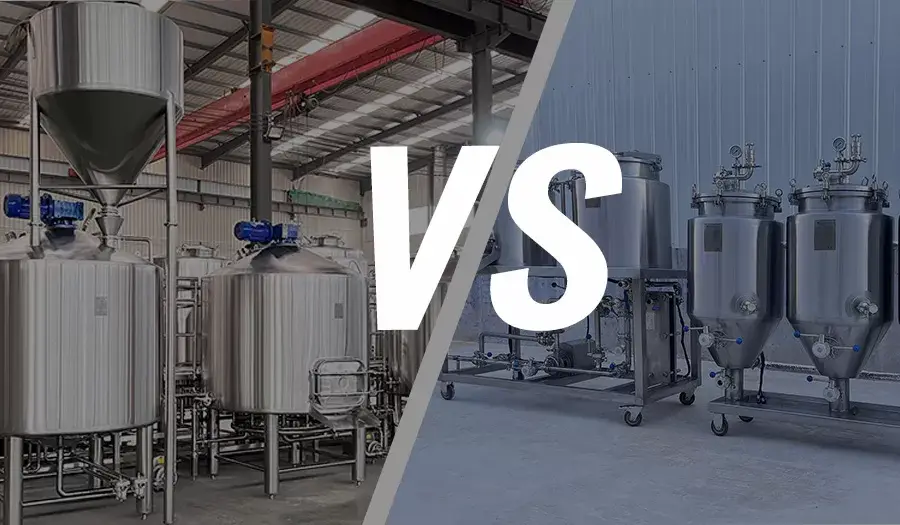

Home brewing equipment is designed for small-scale production, with batch sizes of 1 to 10 gallons (3.8 to 38 liters). Commercial brewery equipment, but, is built for large-scale production, producing hundreds to thousands of gallons (thousands to tens of thousands of liters) per batch.

Formula raw materials are different

Homebrewers have the freedom to create unique beer recipes based on their preferences. They can experiment with different combinations of ingredients and styles, resulting in a variety of flavors and aromas. In contrast, commercial breweries stick to a few flagship beers and established styles, although some may offer seasonal or limited-edition beers.

Commercial breweries often have access to a wider range of ingredients than home breweries because they have the resources to buy ingredients from around the world. This means commercial breweries can use more expensive ingredients, such as fresh hops, which can give the beer a more complex flavor. Homebrewers, but, are often limited to the ingredients they can find , which may limit the types of beers they can brew.

Different brewing equipment required

Home brewing doesn’t need a lot of equipment and tools, sale a few sample jars or buckets to start producing 1-5 gallons of high-quality beer. Commercial brewing, but, is a different story. Even a small brewery needs to buy a lot of complex equipment, raw materials, and utilities. As beer production increases, some special equipment may be needed. Although the equipment is identical to home brewing equipment, they are much larger.

Here is a checklist of what you need to start a small brewery:

- Brewery equipment (Kettles, boilers)

- Fermentation tanks and bright tanks

- Filter

- Cooling system

- CIP cleaning system

- Pipeline

- Filling or bottling equipment

- Supply: hops, malt, yeast, bottles, labels and packaging.

- Utilities: electricity, steam and water, etc.

The process is different

Commercial breweries use more automated processes than home breweries because they have the resources to invest in this equipment. This results in a more consistent product because automated processes are less likely to introduce errors. Homebrewers, , use a more manual process, which gives them more control over the brewing process. Yet, this can also lead to more variation in the final product, as there is more room for human error.

Efficiency is different

Commercial brewery equipment is optimized for efficiency and designed to produce large quantities of beer of consistent quality in the most cost-effective manner. It includes features such as heat exchangers for rapid cooling, large-capacity boilers, and high-efficiency filtration systems. Because home brewing equipment is smaller and focuses on experimentation and personal enjoyment, the same level of efficiency may not be prioritized.

Constraints on Commercial Brewing

The biggest difference between a typical home brewery and a commercial brewery is the constraints of commercial brewing. The great thing about homebrewing is that you can brew any beer you want. If your imaginary brewing recipe turns out , you can throw it away and only lose $20. But if a commercial brewery produces at least 3 barrels of beer per batch, you still have to throw it away and you’ll be out hundreds or even thousands of dollars. At some point, when you move to commercial brewing, you lose your creative license. Of course, in many breweries, there will be dedicated brewers who conduct small-batch trial brewing. Only when the beer style and taste meet the requirements will they be brewed in large batches.

Filtration and pasteurization

Commercial beer is filtered and pasteurized to remove yeast and bacteria from the beer and extend its shelf life. This is done because commercial breweries need to be able to sell their beer to a wide audience and they need to ensure the beer stays fresh on the shelves.

Homebrew beers are not filtered or pasteurized, which gives them a fresher, more flavorful flavor. Yet, this also means that homebrew beer has a shorter shelf life and needs to be consumed sooner rather than later.

Equipment cleaning methods are different

During the beer production process, the beer brewing equipment must be kept clean. Not only must it be free of dirt, but it must also be free of bacteria. , homebrewers use bleach and detergents to clean equipment and disinfectants to control bacterial counts. If your home brewing equipment is faded, worn, or scratched, it will need to be replaced with other home brewing equipment. Commercial breweries not only need to use the things mentioned above to clean their equipment, but they also need to use many harsh and corrosive chemicals to scrub and sanitize.

Which method is more suitable for you?

The taste of beer may be similar between home brewing and commercial brewing, but the process of completing the brew is indeed different. Since both beers have their own merits, choosing between them can be a bit difficult.

The following factors can help you:

- Personal preferences and health goals. Some people prefer the taste, aroma and extra vitamin content of homemade beverages, while others feel safer purchasing commercial beverages.

- Home brewing methods, techniques and hygiene. Failure to meet standards may result in product spoilage. If maintained, it can produce a quality product.

- Commercial beer comparison. Which commercial beer would you compare your home brew to? What are its nutritional contents? Calorie content? Alcohol content?

No matter which one you prefer, I hope these can help you when you are confused.

Heyɑ just wanted to give you a brief heads up and let you knoԝ a few of the

pictures aren’t loading properly. I’m not sure why but I think its a linking issue.

I’ve tried it in two different ԝeb browsers and both

show the same results.

Hello! I just wish to give you a big thumbs up for your excellent information you have got here on this post.

I will be coming back to your website for more soon.