What You Will Learn

- All the gear you need to make craft beer

- How much it costs to get started

- Best equipment for your size and budget

- Step-by-step setup guide

Essential Craft Beer Equipment for Beginners

The craft beer world is booming. But many new brewers face a big problem: picking the right equipment from hundreds of choices. They waste money on wrong or poor-quality items. The market has so many options that it’s easy to feel lost.

This challenge grows when you see the price tags. Do you need to spend thousands? What if you buy the wrong thing? The stress of making these choices stops many would-be brewers before they even start.

The good news: you can find the perfect brewing setup with the right guidance. Whether you’re just starting or growing your brewery, there’s equipment made just for your needs and budget.

Must-Have Equipment

Every brewer needs these basic items:

- Fermenters – Where your beer becomes beer

- Brew kettles – For boiling the wort

- Mash tuns – Where grain meets water

- Bottling systems – For packaging your beer

The quality of these core items directly affects your beer’s taste. Stainless steel fermenters last longer and are easier to clean than plastic. They help make better beer by avoiding contamination.

DIY vs. Pre-Made Kits

| Kit Type | Pros | Cons | Cost Range |

|---|---|---|---|

| DIY Equipment | More customization, Learn more | Takes time to gather, May lack instructions | $500-$2,000 |

| Pre-Made Kits | Easy to start, Everything matches | Less flexible, Higher cost | $1,000-$5,000 |

Many new brewers start with homebrewing kits that include all the basics. These kits make getting started simple.

“We started with a basic kit but soon wanted to upgrade. If I’d known then what I know now, I would have invested in quality stainless equipment from the start,” says Tom, owner of Hoppy Days Brewery.

How to Choose the Right Equipment

The Budget Dilemma

Many new brewers face this tough question: “How much should I spend?” This is a real struggle. Spending too little means replacing equipment soon. Spending too much might put your business at risk.

This worry gets worse when you see the wide price range – from $2,000 home setups to $50,000+ commercial systems. How do you choose wisely without overspending?

The solution is to match your equipment to your real needs and growth plans. Look for quality equipment that will grow with you but won’t break the bank.

Size & Capacity Considerations

The global craft beer market is huge – $142.6 billion in 2024. But your equipment needs to match your specific goals:

- Nano brewery (1-3 barrels): Perfect for testing recipes and small venues

- Microbrewery (4-15 barrels): Good for local taprooms and distribution

- Small commercial (15+ barrels): For wider distribution and growth

The key is buying equipment that matches your current needs while allowing some room to grow. Many brewers regret buying too small and having to replace everything later.

Material Guide: Why Quality Matters

Stainless steel dominates the market for good reason. It makes up 85% of equipment sales because:

- It doesn’t affect beer flavor

- It lasts 25+ years with proper care

- It’s easy to clean and sanitize

Stainless Steel Fermentation Tank & Bright Tanks are essential for quality beer production. These tanks keep your beer safe and tasting great during the critical fermentation process.

Some brewers try to save money with plastic, but this often becomes expensive when they need to replace it quickly. The brewing process involves heat, pressure, and sanitizing chemicals – all of which can damage lower-quality materials.

Step-by-Step Brewing Setup Guide

Setting Up Your First Brewing System

The path to great beer starts with proper setup. Here’s what you need:

- Planning the space

- Good drainage

- Proper ventilation

- Enough electrical capacity

- Equipment layout

- Logical workflow design

- Space for moving around safely

- Room for future growth

- Utilities connection

- Water sources and filtration

- Electrical needs

- Waste management

Many new brewers face frustrating delays because they didn’t plan their space well. A good layout saves time and prevents costly mistakes.

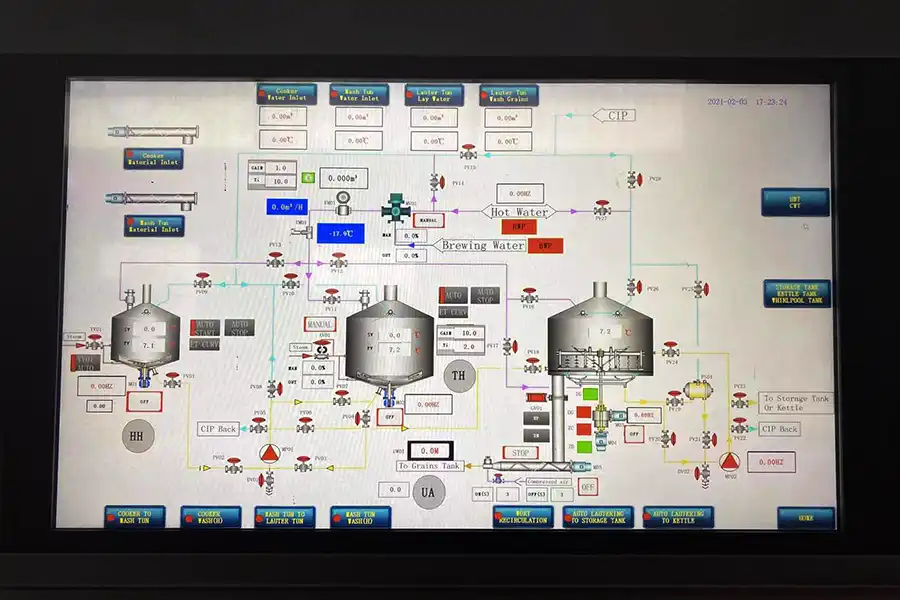

Automation Tools That Save Time

Modern brewing benefits from smart technology. Brewing software can:

- Track fermentation progress

- Control temperatures precisely

- Monitor pressure levels

- Alert you to any problems

Automated brewing systems reduce human error and free up time. They help make consistent beer batch after batch. This consistency is key to building a loyal customer base.

The data shows that 60% of new breweries now use software for fermentation control. This isn’t just a luxury – it’s becoming standard practice for quality and efficiency.

Top Craft Beer Equipment Brands

Leading Manufacturers Compared

The market offers many options, but quality varies widely. Some brands have proven track records:

| Brand | Known For | Price Range | Special Features |

|---|---|---|---|

| Spike Brewing | Durability | Heavy-duty construction | |

| Ss Brewtech | Innovation | Temperature control | |

| Blichmann | Precision | $ | Advanced features |

| Micet Group | Custom Solutions | ParseError: KaTeX parse error: $ within math mode$$$ | Full-service support |

When evaluating equipment, look beyond the price tag. Consider:

- Warranty terms

- Customer support

- Replacement parts availability

- User reviews

The global brewery equipment market reached $20.8 billion in 2023 and continues to grow. This growth means more options but also more need for careful selection.

Trust Signals to Look For

When buying brewing equipment, check for:

- Quality certifications – ISO standards, safety ratings

- Material grades – 304 or 316L stainless steel

- Manufacturing experience – Years in business

- Support network – Service centers, training options

Companies with global service networks can provide better support. For example, some manufacturers have established service centers across multiple countries to help customers quickly.

Cost Breakdown: Starting a Brewery

Real Investment Figures

Building a brewery requires careful financial planning. Here’s what to expect:

| Equipment Type | Small Scale (1-3bbl) | Commercial (10+bbl) |

|---|---|---|

| Brewing System | $10,000-$30,000 | $100,000-$500,000 |

| Fermenters | $5,000-$25,000 | $30,000-$100,000 |

| Packaging Line | $10,000-$50,000 | $100,000-$500,000 |

| Cooling System | $5,000-$15,000 | $30,000-$100,000 |

| TOTAL RANGE | $30,000-$120,000 | $260,000-$1,200,000+ |

These numbers show why careful planning is so important. The 1000L Beer Brewing System offers an excellent middle ground for those starting out but planning to grow.

Hidden Costs to Plan For

Many new brewery owners are shocked by expenses they didn’t plan for:

- Installation costs – Often 15-20% of equipment cost

- Training – Staff need to learn the equipment

- Permits and licenses – Vary by location

- Utilities upgrades – Many buildings need electrical work

- Maintenance supplies – Cleaning chemicals, replacement parts

Planning for these costs from the start prevents painful surprises later.

Maintenance & Safety Best Practices

Keeping Equipment Running Smoothly

Good maintenance saves money and makes better beer. Follow these tips:

- Daily cleaning routines

- Clean after every use

- Use proper chemicals

- Follow temperature guidelines

- Weekly maintenance

- Check all seals and gaskets

- Test pressure on systems

- Inspect electrical components

- Monthly deep cleaning

- Disassemble and clean valves

- Check all welded areas

- Run acid wash on appropriate parts

CIP systems (Clean-in-Place) save time and improve cleaning results. They pump cleaning solution through the system automatically.

Safety First Approach

Brewing has real dangers including:

- Hot liquids

- Pressure vessels

- Heavy equipment

- CO2 buildup

Every brewery should have:

- Written safety procedures

- Regular staff training

- Proper ventilation

- Emergency equipment

The data shows that breweries with regular safety training have 40% fewer accidents. This investment in safety protects both people and profits.

Scaling Your Brewery

When It’s Time to Grow

Most successful breweries eventually need to expand. Watch for these signs:

- You can’t keep up with demand

- You’re brewing at full capacity constantly

- Customers are asking for more variety

- You’re entering new markets

Scaling a brewery takes careful planning. The 2000L 3 Vessel Microbrewery Equipment provides an excellent platform for growth while maintaining quality.

Sustainable Brewing Practices

Modern breweries are focusing on sustainability:

- Water recycling – Reduces usage by up to 30%

- Energy efficient systems – Cuts utility bills

- Waste reduction – Spent grain can be repurposed

- Solar power – Some systems can be solar-powered

These practices not only help the planet but also reduce costs. With energy accounting for 15-20% of brewery expenses, efficiency improvements make a real difference to the bottom line.

Expert Solutions for Common Problems

Overcoming Brewing Challenges

Every brewer faces problems. Here are solutions to common ones:

Problem #1: Inconsistent temperatures

- Solution: Install glycol cooling systems with precise controls

Problem #2: Limited floor space

- Solution: Consider vertical tank arrangements and efficient layouts

Problem #3: Scaling production

- Solution: Look for modular systems that can grow with your business

Problem #4: Finding expert help

- Solution: Work with manufacturers that offer design and support services

The right partner can help solve these problems before they affect your beer. Companies with experience in brewery design bring valuable insights to your project.

Customization Options

No two breweries are alike. Your equipment should match your specific needs:

- Custom tank sizes to fit your space

- Specialized equipment for unique beer styles

- Integration with existing systems when upgrading

- Branded equipment for taproom visibility

The 1500L 3 Vessel Brewery Equipment offers excellent customization options for growing breweries.

Global Trends in Craft Beer Equipment

What’s Driving the Market

The craft beer equipment market is changing fast. Key trends include:

- Automation growth – 75% of industrial breweries now use IoT sensors

- Sustainability focus – 40% of breweries prioritize energy-efficient equipment

- Modular designs – Allowing easier expansion

- Mobile solutions – Portable brewing systems for events and testing

The global market is expected to reach $32.8 billion by 2030. Asia Pacific shows the fastest growth at 10.5% CAGR.

Regional Market Insights

| Region | Market Share | Notable Trends |

|---|---|---|

| Europe | 38.1% | Traditional brewing, beer tourism |

| North America | 28.8% | Taproom-focused, innovative styles |

| Asia Pacific | Growing at 10.5% | New markets, fusion styles |

Each region has unique equipment needs based on styles, climate, and customer preferences. Working with manufacturers who understand these differences helps ensure success.

Craft Beer Market Overview 2024-2030

Quick Facts

Average Equipment Costs

$30-120k

$260k-1.2M

FAQs About Craft Beer Equipment

Q: What’s the difference between a conical fermenter and a standard one?

A: Conical fermenters have a cone-shaped bottom that collects yeast and sediment, making harvesting yeast and cleaning easier. They improve beer clarity and save time.

Q: Can I use homebrewing equipment for commercial purposes?

A: While technically possible for very small batches, commercial brewing requires equipment that meets health regulations and can handle the volume. It’s best to invest in proper commercial equipment.

Q: How do I maintain fermentation temperature control?

A: Glycol cooling systems are the industry standard. They circulate cold glycol through jackets on fermentation tanks to maintain precise temperatures.

Q: What size brewery should I start with?

A: Match your equipment to your business plan. If you’re opening a taproom, a 3-10bbl system is often ideal. For distribution focus, 10+bbl is usually better.

Q: How long does brewing equipment last?

A: Quality stainless steel equipment can last 25+ years with proper maintenance. The return on investment makes quality equipment worth the higher upfront cost.

Making Your Brewery Dream Real

The craft beer industry continues to grow despite challenges. With $142.6 billion in global market value and projected growth to $329.7 billion by 2033, opportunities remain strong for those with the right approach.

Success in brewing requires three key elements:

- Quality equipment that matches your needs

- Knowledge of brewing science and business

- Support from experienced partners

The difference between struggling and thriving often comes down to having the right equipment partner. Some manufacturers offer complete support from design through installation and beyond, ensuring your success.

Your Next Steps

As you plan your brewery, consider these actions:

- Define your beer styles and volume goals

- Measure your available space carefully

- Create a realistic budget with contingency funds

- Research equipment providers thoroughly

- Ask for customer references and case studies

The brewing community is supportive. Learn from those who have walked this path before you.

Conclusion

Building a successful brewery takes the right equipment, knowledge, and support. The craft beer industry continues to grow, with plenty of room for brewers who make quality products efficiently.

The key is finding equipment that fits your specific needs and working with partners who understand the brewing business. Some manufacturers offer complete solutions from design through installation, with global support networks to help you succeed.

With the right equipment partner, your brewing dream can become reality. The perfect brewing system is one that helps you make great beer consistently while adapting to your growth over time.

This guide was created based on market research, brewer interviews, and industry data. Equipment recommendations are based on quality, durability, and value.