자동 추출 시스템

자동화된 브루잉 시스템이 필요한 이유는 무엇인가요?

시중에는 자동 추출 시스템을 위한 옵션이 점점 더 많아지고 있습니다. Micet Group의 다양한 지능형 디자인, 사용 편의성 및 사용자 지정 기능을 통해 매우 재미있고 효율적으로 추출할 수 있습니다. 이 고품질의 멋진 기술을 이용한 브루잉을 좋아하게 될 것입니다. 우리는 맥주 양조를 좋아하지만 모든 사람이 양조 과정의 모든 세부 사항을 알고 싶어 하는 것은 아니라는 것도 잘 알고 있습니다. 핵심은 자동화된 시스템을 사용하여 고품질의 맥주를 생산하는 것입니다.

시스템이 덜 자동화되어 있을수록 사용자가 직접 해야 할 일이 많아집니다. 곡물 추가, 홉 추가, 발효기에 맥주 넣기, 맥주통이나 병에 채우기 등이 이에 해당합니다. 따라서 자동화 시스템은 양조 과정에서 많은 노동력을 줄일 수 있습니다. 완전 자동화 시스템은 기본적으로 모든 과정을 자동으로 수행합니다. 버튼 몇 개만 누르면 됩니다.

자동 추출 시스템 비용이 많이 드나요?

많은 사람이 자동화된 브루잉 시스템이 막대한 투자가 될 것이라고 생각합니다.

사실 소규모 양조장의 자동화는 대규모 양조장의 자동화와는 매우 다릅니다. 모든 자동화 프로세스가 아니라 필요한 자동화 프로세스만 자동으로 설계되기 때문에 큰 투자가 필요하지 않습니다. 자동화의 합리적인 도입으로 인해 자동화 수준이 높은 장비는 양조자의 양조 재미를 보장할 뿐만 아니라 많은 시간과 에너지를 절약할 수 있습니다. 양조장 장비의 크기에 따라 반자동 PLC 제어 시스템과 원격 제어가 가능한 완전 자동 PLC 제어 시스템 등 여러 가지 자동 레벨의 양조장을 선택할 수 있습니다.

자동화된 양조장에는 어떤 기능이 있나요?

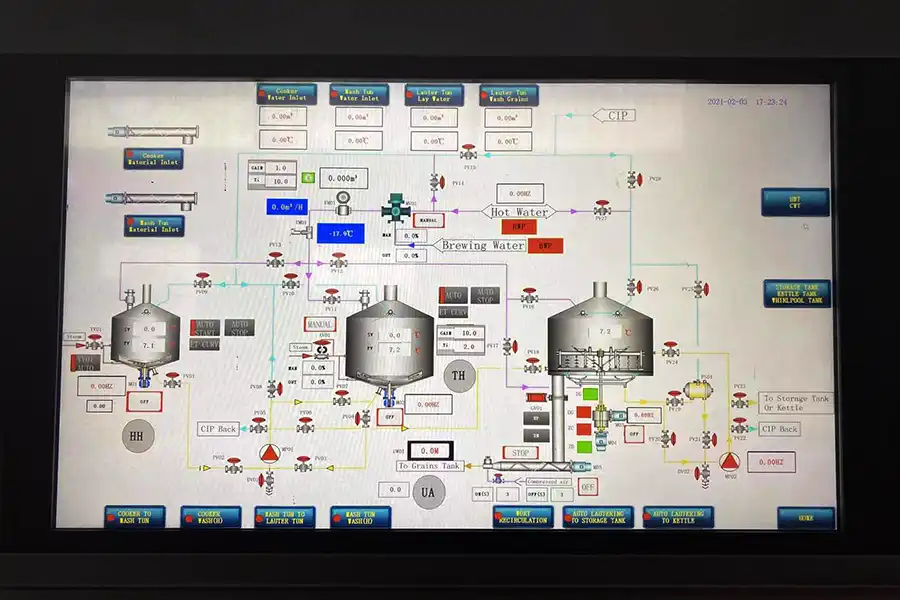

주요 기능은 공압 버터플라이 밸브, 지능형 센서 및 기타 제어 하드웨어를 통해 실현되며 지멘스 PLC의 소프트웨어 프로그래밍 제어 프로그램을 통해 연속 및 자동 양조를 실현합니다. 전자동 PLC 제어는 터치 스크린에서 직접 밸브를 작동할 수 있으며 동시에 액체 레벨, 물량 및 맥아 즙 볼륨을 자동으로 모니터링하고 제어 할 수 있습니다.

- 매시 튠: 매싱 온도와 혼합 속도를 미리 편집할 수 있습니다. 다양한 맥주 매싱 공정의 다양한 요구 사항에 따라 양조 공식을 입력하고 공식을 클릭하여 온도 제어 매개 변수를 자동으로 로드할 수 있으며, 동시에 매싱 온도 곡선을 제어하여 자동 단계 매시 가열을 달성할 수 있습니다.

- 로터 툰: 압력 센서, 변위 센서, 탁도 센서를 사용하여 끓이는 과정, 자동 환류, 자동 여과를 자동으로 제어하여 주전자 및 곡물 스파징을 추출하고 실시간으로 맥아즙 탁도를 모니터링하며 여과 속도, 레이크 속도 및 깊이를 자동으로 조정합니다.

- 양조 주전자: 끓이기 시작/끊기 시간, 강도, 속도 등 끓이기 프로세스 파라미터를 미리 설정하고 홉을 넣을 홉 필러를 미리 구성한 후 설정 시간에 따라 자동으로 홉을 추가합니다. 높은 발전과 안정성을 갖춘 MICET 설계로 연속 매싱 생산(3시간마다 한 배치의 맥아 즙)을 실현할 수 있습니다.

- 월풀, 맥아즙 냉각 및 물 제어: 맥아 즙의 냉각 매개 변수를 설정하면 맥아 즙 냉각 후 자동 온도 제어를 위해 열교환기를 통해 발효에 들어가고 냉수 및 온수는 자동 액체 레벨 제어 및 자동 밸브를 실현하여 물을 추가 할 수 있습니다. 자동 온수 및 냉수 혼합.

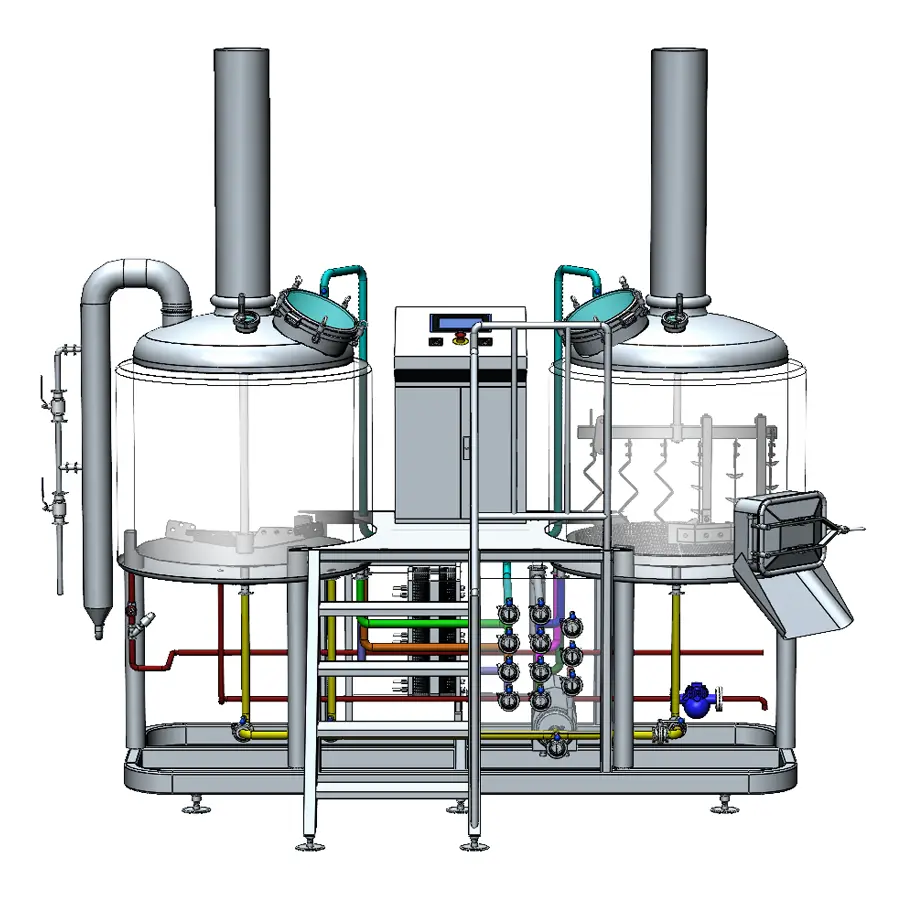

양조장 500L 3D

>미셋 그룹 전자동 브루잉 시스템의 장점은 무엇인가요?

1. 자동화 수준 선택 가능

각 주문의 자동화 수준은 양조자의 요구와 예산에 따라 사용자 정의 할 수 있습니다. 자동화는 무한히 개선할 수 있지만 각 고객은 가장 핵심적이고 중요한 생산 공정이 완전히 자동화되어 있고 보조 노동 강도가 높지 않으며 수동 지원도 좋은 선택) 등 자신의 조건에 따라 자동화 정도를 선택하는 것이 좋습니다.

2. 원클릭 자동 추출 프로세스 시각화 시작

온도, 액체 레벨, 압력, 탁도, 유량, 당도, 밸브, 펌프 속도 등과 같은 변수를 온라인으로 표시하고 제어할 수 있습니다. 제어 가능한 모든 단위는 수동으로 편집할 수 있습니다. 완전 자동 모드에서는 모든 파라미터를 설정하거나 레시피를 선택하기만 하면 클릭 한 번으로 모든 양조 과정을 시작하고 완료할 수 있습니다.

3. 생산 효율성 향상 및 확장 용이성

Micet 자동 양조장 장비는 맥아즙 품질을 유지하면서 높은 생산 효율과 높은 원료 당 추출을 제공합니다. 각 맥즙 생산 배치의 시간을 절약하고 4시간 만에 1배치, 10시간 만에 4배치 맥즙을 생산할 수 있습니다. 향후 생산 확장이 필요할 때 발효 탱크를 바로 추가할 수 있습니다.

4. 맥주 맛은 보장하면서 노동력 절감

모든 종류의 맥주를 생산할 수 있으며 공식과 공정 매개 변수 만 있으면 작동하기 쉬워 고급 양조자를 찾기 어려운 문제와 생산 과정의 높은 인건비 문제를 해결합니다. 양조 경험은 없지만 맥주에 대한 열정이 있는 초보자에게 좋은 선택입니다.

5. 포괄적인 사전 판매 및 애프터 서비스

구매하기 전에 쇼룸에 방문하여 실제 작동 또는 온라인 비디오 경험을 경험할 수 있으며, 공동 확인을 위해 3D 모델로 장비 설계를 제공합니다. 배송 전에 실제 생산을 시뮬레이션하여 기계를 테스트하고, 비디오를 통해 테스트 프로세스를 보거나 공장을 방문하여 직접 기계를 테스트 할 수 있습니다.

6. 오프사이트 모니터링 및 원격 액세스

휴대폰에 현장 관리자를 설치하면 휴대폰을 사용하여 실시간으로 발효 진행 상황을 원격으로 모니터링하고 파악할 수 있으며 양조장에 도착하기 전에 미리 뜨거운 물을 데울 수 있습니다. 이 경우 양조자의 시간이 크게 해방됩니다. 외출 중에도 휴대폰을 열어 발효기의 실시간 상황을 확인할 수 있습니다. Micet 엔지니어가 원격으로 설치 및 디버깅을 제공하고 추후 업그레이드 및 업데이트를 포함한 평생 서비스를 제공합니다.

질문이 있으신가요?

당사는 양조업체를 위한 최첨단 자동 양조 시스템을 전문적으로 제공하여 생산 효율성을 개선하고 수동 개입을 줄이며 각 맥주 배치의 일관된 품질을 보장합니다. 소규모 작업장이든 대규모 생산자이든, 당사의 시스템은 정확한 온도 제어, 발효 모니터링 및 생산 스케줄링을 지원하여 필요에 따라 맞춤화할 수 있습니다.

전화:

+86-531-82979225

WhatsApp:

+86-18615260186