Beer is one of the most delicate and labile beverages from the sensory point of view. It has a complex but moderate taste and aroma and shows a poor flavor stability compared to other alcoholic beverages. Although over one thousand flavor components have been identified in beer, most of them are at the concentrations under the respective threshold values. Even so, all the components may contribute more or less to the flavor of the product. Beer flavor is changeable with a wide variety of influences which occur at all stages of the brewing process and during storage after packaging.

Preventing off-flavors is one of the most serious problems in the brewing industry, as most consumers judge products primarily on the quality of their flavors. The main factors that lead to the off-flavors of craft beer can be summarized into the following three aspects:

- The raw and auxiliary materials, water, yeast, etc. These material are used in the production process, the quality of these materials and the physical, chemical and biochemical changes of the ingredients contained in the beer production process have the greatest impact on the taste of beer.

- The production equipment used in the production process, especially the equipment that is in direct contact with the raw material, including equipment structure, texture, and level of automation control are also important factors affecting the quality of beer taste.

- Improper management of the process methods, process conditions and process operations adopted in the production process will also cause the beer to produce peculiar smell.

What is Spontaneous fermentation beer?

Spontaneous fermentation refers to relying on the natural microflora in the air to ferment, rather than cultivated yeast. In the eyes of many beer lovers, naturally fermented beer is the closest to the original taste of beer. While traditionally fermented beer has predictable characteristics of specific yeast strains, spontaneous fermentation relies on geography and local microflora. Much like how wine features terroir, the idea that the environment gives beverages a sense of place.

On the market, the Spontaneous fermentation beers we usually come into contact with are Lambic beers from Belgium. Belgian farmers choose where to work according to the beer they are brewing. Uncovered brewing barrels filled with local rubic wheat juice are placed on the Seine River in Brussels, where wild yeast floating in the air enters the wort and ferments. The beer brewed in this way is cloudy yellow in color, has more foam, and is sweet and sour. However, due to the use of wild yeast in the air, the fermentation process is not artificially controlled, so the taste of the rubic beer produced is different each time.

What is Off-Flavors in Beer?

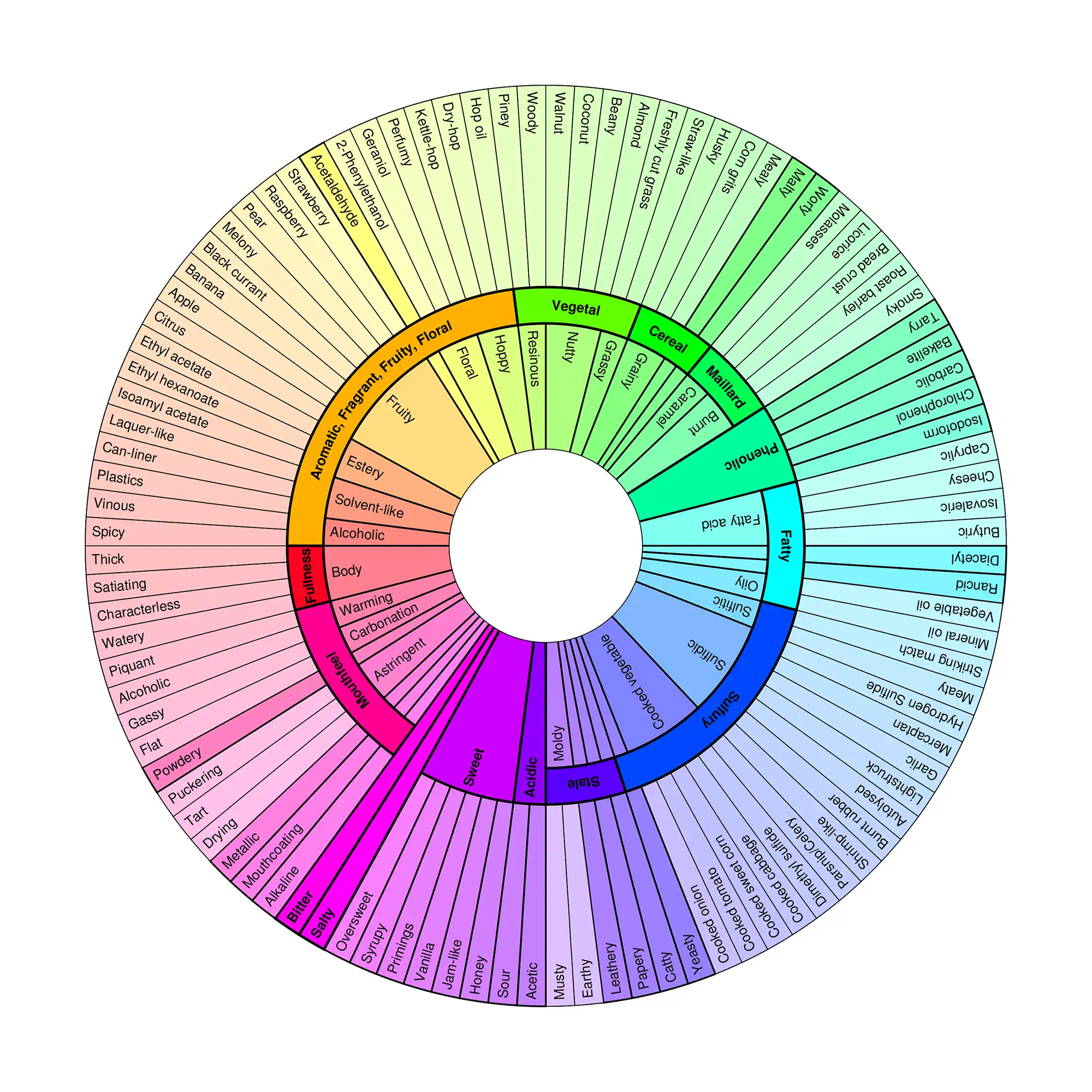

Off-flavor refers to the taste or aroma that should not be present in beer, and is one of the criteria for measuring the quality of beer. We’ve listed the main off-flavors that occur in beer, and when smelling these, they need to be noticed, because these beers may have gone wrong in the brewing or storage process.

Off Flavors and How to Avoid it

To identify these off-flavors, you need both experience and time. With this list, we try to concise all the learnings you will ever need to recognize, control, and eliminate these off-flavors.

Flavour Compounds in Beer

1. Acetaldehyde

Descriptors

Green apples, freshly cut pumpkin

Cause

- Yeast is produced naturally during fermentation and could converted to ethanol (alcohol) by yeast.

- When the alcohol content in the liquor is high, or the yeast inoculum is insufficient, the process of acetaldehyde conversion will slow down.

- Some bacterial contamination can also cause green apple flavors.

Control measures

The beer after the main fermentation is poured into barrels/bottled and left for a few months to allow enough time for the yeast to convert the acetaldehyde into ethanol. Use high quality yeast to ensure adequate yeast inoculum for the initial wort. Some brewers will also add a little extra fresh wort and live yeast after the beer reaches the final specific gravity to effectively convert acetaldehyde into alcohol.

2. Alcoholic

Descriptors

Overly strong alcohol taste can be unpleasantly bitter, acetone, paint thinner, pungent, sharp, and unpleasant; there may also be an uncomfortable burning sensation in the throat.

Cause

- Usually caused by higher alcohols/fusel alcohols (propanol, butanol, isobutanol, isoamyl alcohol, phenolic alcohol, tyrosol).

- Fermentation temperatures that are too high, oxidation, or yeast/sediment staying in the beer for too long can cause this flavor.

- High-alcohol beers such as barley beer or strong ales can have a small amount of pleasant alcohol flavor; however, the alcohol flavor will be more pronounced in light-style beers.

Control measures

Avoid fermentation temperatures above 26.7°C. If the beer is going to be in the fermenter for an extended period of time, remove as much sediment from the bottom of the barrel as possible (it can be poured).

3. Astringent

Descriptors

Sharp, sour tannins, dry tongue, feels like powder or metal in the mouth.

Cause

- Tannins and polyphenols (found in grain skins/hops/fruit skins) will be the main culprits

- Or a bacterial infection (Acetobacter vinifera gives the vinegar smell).

- Soaking the malt/grain too long (too long for sugar development), or excessively crushing the malt will increase tannin leaching.

- Sugar pH above 5.2-5.6 will produce more astringency.

- Excessive hop input.

Control measures

- Avoid over-milling the malt/grain, the best milling condition is: the husk is broken, but not crushed.

- The temperature of the washing water should not exceed 82°C (77-78°C is recommended) to avoid excessive washing.

- Do not put the fruit into the wort to boil, it is recommended to sterilize it in 75-80℃hot water for 15-30min and put it into the fermentation barrel.

- Make sure the amount and variety of hops match the style of the beer.

- Don’t mix brown scum that sticks to the walls of the fermenter into the beer (it will sit quietly on the walls if you don’t touch it).

4. Chlorophenol

Descriptors

Plastic, vinyl, iodine smell

Cause

- Over-chlorinated tap water was used for brewing/washing equipment.

- Using iodine- or chlorine-based detergents can also cause a medicinal smell.

- Certain wild yeasts invade.

Control measures

Use a filter to remove chlorine from tap water; or boil tap water for 15 minutes (to evaporate chlorine), then cool to room temperature. If using bleach to disinfect,should rinse with hot boiled water.

5.Cidery

Descriptors

Cider, Wine, Acetaldehyde

Cause

The most common reason is the use of too much sucrose or glucose, as long as no more than 450 grams of sugar is used per 19 liters of beer, the cider taste will not be produced.

Control measures

- Reduce the amount of sucrose or glucose and replace with malt extract (no cider taste).

- The honey ferments well and doesn’t develop a cider taste, but will leave a more or less honey taste depending on the amount.

- If it is caused by a yeast strain, storing the beer at low temperatures for a while can weaken the flavor.

6.Diacetyl

Descriptors

Butter, rotten butter, butterscotch, slippery in the mouth and the tongue

Cause

- All yeasts naturally produce diacetyl during fermentation, and as the fermentation draws to a close, the yeast will gradually absorb the diacetyl into the body and convert it into substances that have little effect on the flavor.

- Flocculation of yeast (yeast cells clumped together) is very high, or the viability is weak, resulting in variation

- The oxygen content of the wort is too high or too low

- Fermentation temperature too low

- Insufficient boiling time will produce too much diacetyl, in the yeast not being able to absorb it

- For lagers, the diacetyl flavor is a drawback; but a small amount of diacetyl flavor might be pleasing in an ale.

Control measures

- Use yeast with high activity, good quality and medium flocculation (Yeast with high flocculation will settle out quickly before diacetyl is recovered).

Yeast was activated before use. - Allow enough oxygen to dissolve in the wort before inoculating the yeast, but avoid excess oxygen after inoculation.

- Let the yeast be at the right fermentation temperature and have a long enough fermentation time to perform sufficient fermentation work.

7. Dimethyl Sufides, DMS

Descriptors

Cooked veggies, creamed corn, cabbage, tomatoes, shell aquatics/oysters.

Cause

- During the malting process, S-melthy methoione (SMM) will first be produced in the malt, and then during the roasting process of the malt, SMM will be converted into DMS when heated, and it will volatilize away with heating.

- Dark malts also contain less DMS due to longer baking times.

- DMS is more common in pale ales and pale lagers (using pale malts).

Control measures

- DMS will evaporate with heat when cooking the wort, so make sure the wort is fully boiled for at least 1 hour (some brewers will also boil the wort for 90 minutes to remove as much DMS as possible).

- Do not cover the cooking pot completely when boiling, otherwise condensation on the lid will drip back into the wort with DMS.

- After cooking, cool the wort as quickly as possible because DMS will continue to be produced at high temperatures.

- Vigorous fermentation will produce a lot of carbon dioxide, which will take away DMS, Therefore, it is necessary to use high-quality yeast.

8. Estery/Fruity

Descriptors

Banana (dominant), pear, strawberry, raspberry, grapefruit

Cause

- The ester taste comes from the metabolites naturally produced by yeast during fermentation, and different yeasts produce different degrees of ester taste.

- Some ales, such as Belgian ales, German wheat beers are expected to have this taste. But an overly strong ester smell is inappropriate.

- Insufficient yeast inoculum, or high fermentation temperature can lead to more estery flavors.

Control measures

- Choose a yeast that matches the style of the beer; German wheat beer and Belgian ales produce more fruity ester character.

- Make sure that the yeast inoculum is enough and that the wort has the correct oxygen content.

- Avoid fermentation temperature higher than 23.8°C, as esters will increase significantly above this temperature.

- Fermentation at 15.5-18°C will effectively reduce lipids, and of course the fermentation speed will also slow down.

9. Grassy

Descriptors

Freshly cut green grass, musty smell

Cause

- The grains or extracts are moldy or contaminated with bacteria, commonly found in old malt.

- Inappropriate handling/packaging/storage of hops.

Control measures

- Store grains and malt in a cool, dry, dark place; make sure all ingredients are no fading and no odor before brewing.

- The malt is freshly ground before brewing, and the ground malt should be used within 2-4 weeks.

- Use high-quality hops and store according to the instructions.

10. Husky/Grainy

Descriptors

Raw grains, dry, somewhat astringent from tannins or oxidation.

Cause

Overmilled malt and the use of deep roasted malt can both cause this flavor.

Control measures

- Avoid using overly milled/crushed malt.

- When using deep roasted malt for whole grain brewing, let the ground roasted malt sit for 1-2 weeks to allow harsh smells and flavors to evaporate.

- For beer with a strong husk flavor, you can store the beer at a low temperature for a month or two, and the odor-causing substances will sink to the bottom.

11. Medicinal

Descriptors

cough syrup, mouthwash, band-aid, smoke, spicy cloves

Cause

- Caused by a variety of phenolic substances.

- Incorrect pH, water level, and temperature during mashing/grain washing.

Detergents containing chlorine or iodine were used. - Yeast also produces some clove flavors, especially in German wheat beers and some other wheat beers.

Control measures

- Optimize the way of mashing/grain washing.

- Choose a yeast strain that matches the beer style.

12. Metallic

Descriptors

A taste similar to metal, iron, coins, blood is felt in the front of the mouth and in the back of the throat.

Cause

- Boiling equipment, bottle caps, and Keg barrels are of poor quality, with metal residue/escape, mainly iron, aluminum, and steel.

- Brewing water contains too much iron ions.

- Malt is not stored properly.

Control measures

- Use stainless steel brewing equipment/utensils as possible.

- Avoid wort and beer with iron utensils; avoid brewing with iron-containing water (such as unfiltered well water).

- Use fresh, properly stored malt.

13. Moldy

Descriptors

mold, mildew on bread

Cause

- Brew or store beer in a dark, damp place.

- Moldy malt/grain was used.

Control measures

- Store the fermenter in a dry, dark place.

- Once the grain/malt is found to be moldy, discard it.

14. Oxidation

Descriptors

Obsolete and not fresh, wet cardboard, sherry, papery, rotting vegetables, pineapple; increased bitterness, rough flavor

Cause

Excessive oxygen exposure when the wort has not completely cooled or after fermentation is complete (although it is beneficial to allow the wort to fully absorb oxygen before inoculating the yeast, it should not be excessive). Excessive free space left in the bottle when bottling.

Control measures

- When transferring fermenting beer to other containers, avoid causing excessive agitation of the beer; it is recommended to use a hose to transfer the beer (do not pour directly) to avoid air bubbles entering the hose.

- There is no need to worry about oxidation when boiling, oxygen is difficult to dissolve; however, during the cooling process of wort (above 26.7°C), you should avoid stirring the wort to incorporate too much oxygen, and perform rapid cooling at the same time (The oxygenation step required for brewing large batches of beer should be performed below 26.7°C).

- When bottling, the recommended free space in the bottle is 3-4 fingers (distance from the bottle mouth); you can also use a bottle cap that can absorb oxygen to reduce the risk of oxidation.

- Open the CO₂ valve when using the Keg bucket to empty the free space of oxygen.

15. Salty

Descriptors

Feel the taste of salt on the tip of the tongue

Cause

Too much calcium sulfate or gypsum salt added to the brewing water.

Control measures

Do not use brewing salt indiscriminately unless you know the original ionic composition of the brewing water and how the salt affects the water quality.

16. Skunky

Descriptors

Skunk, musty, similar to burnt rubber or civet.

Cause

- The alpha acids in the hops break down under UV light and react with the sulfides produced by the yeast to produce thiols.

- The stinky liquid sprayed by skunks contains mercaptans, so the solar odor of beer is also called skunk smell.

Control measures

- Keep the fermenters out of direct sunlight (especially transparent glass fermenters).

- Protect the clear glass fermenter from light by wrapping it in a paper bag or towel.

- Use a brown bottle, which can blocks most of the UV rays and protects your beer from the odor of sunlight longer lasting; neither green nor clear bottles are UV resistant.

17. Solvent-Like

Descriptors

Paint thinners, nail polish remover (acetone), sharp, harsh, and in extreme cases can cause a burning sensation in the tongue and throat.

Cause

Caused by high temperature fermentation and oxidation problems; or use non-food grade plastic products.

Control measures

- The fermentation temperature should not be higher than the optimum temperature upper limit of the yeast.

- Avoid beer oxidation.

- Do not use non-food grade plastic or vinyl equipment.

- Be aware that some food-grade plastics release toxic substances when heated. If plastic products come into contact with wort, you should consult the plastic manufacturer for safe temperatures.

18. Sulfur / Hydrogen Sulfide

Descriptors

Brimstone, lit matches, rotten eggs, raw sausages

Cause

- Yeast naturally produces hydrogen sulfide during fermentation, which gives beer an unpleasant sulfurous taste.

- Many lager yeasts can produce a very strong sulfur-like odor; Ale yeast is less noticeable and unnoticeable with this odor.

Control measures

- Hydrogen sulfide produced during fermentation cannot be avoided, but carbon dioxide takes most of the hydrogen sulfide away.

- After the main fermentation is over, cooling the beer for a month or two will allow the remaining sulphur notes to fade over time.

19. Sour / Acidic

Descriptors

Acetic acid, spicy taste at the base of the tongue

Cause

Extremely strong sour or acetic odors are mainly caused by bacterial or wild yeast infections.

Control measures

- Carefully clean and sanitize your equipment (the most important part).

- Be sure to keep the lid on when cooling the wort to prevent bacteria from falling in.

- If using a plastic fermenter, carefully inspect the inner surface for scratches (which tend to hide bacteria).

- Do not open the lid of the fermenter unless it’s necessary.

- Use high-quality yeast, or perform yeast activation; the sooner the yeast begins to ferment, the more likely it will defeat other contaminating bacteria.

20. Sweet

Descriptors

Too sweet, sweet wort, sweet and greasy

Cause

- For most beers, it is the pursuit of a moderate sweetness. But if the beer tastes like unfermented wort, it’s possible that the yeast prematurely stops fermentation.

- The interrupted fermentation is reflected in the fact that the yeast suddenly stops fermentation after two or three days of fermentation, resulting in the specific gravity of the wort far below the target specific gravity.

- The yeast used has a low alcohol tolerance, resulting in high residual sugar.

- A sudden drop in temperature causes the yeast to go dormant.

- Insufficient hops, resulting in an imbalance of bitterness and sweetness.

Excessive use of fruit-flavored additives, or other sweeteners.

Control measures

- Use high-quality yeast to ensure that the yeast inoculum is matched to the wort concentration; choose the yeast that matches the style of the beer.

- If yeast with a high degree of flocculation (yeast clumping together) is used, the inoculum size can be appropriately increased, otherwise the yeast will rapidly precipitate and cannot sufficiently convert the sugars.

- Using yeast with a high degree of fermentation results in a less sweet, drier beer.

- When brewing beer with a high alcohol content, it is important to add additional yeast nutrients.

- Monitor the fermentation temperature to avoid fermentation temperatures below the recommended temperature range. If the temperature is too low to cause the yeast to go dormant, you can wake the yeast by gently shaking the fermenter and gradually increase the temperature; you can also simply add a little extra yeast to solve the yeast dormancy problem.

- Many experiments to improve the formula: adjust the bitterness, and the amount of sweeteners.

21. Yeasty

Descriptors

yeast, bread, rough, slightly sulfurous

Cause

- The yeast is unhealthy, or mutated, releasing “yeast odor” into the beer. If the yeast carcass is left in the beer for a long time, the yeast could be autolyzed (explanation of yeast autolysis), then releasing more rough sulfur flavors.

- If the yeast does not flocculate well, it will also taste yeasty.

- For bottled home-brewed beer, if the yeast at the bottom of the bottle is accidentally poured into the glass when pouring the beer, it will also cause a yeasty smell.

Control measures

- If the beer needs to stay in the fermenter for a long time, it can be swapped, which means transfer the beer (without bottom settling) to a new fermenter / bottle / Keg.

- For beer that needs to be fermented twice in the bottle, keep the cloudy yeast liquid at the bottom when pouring