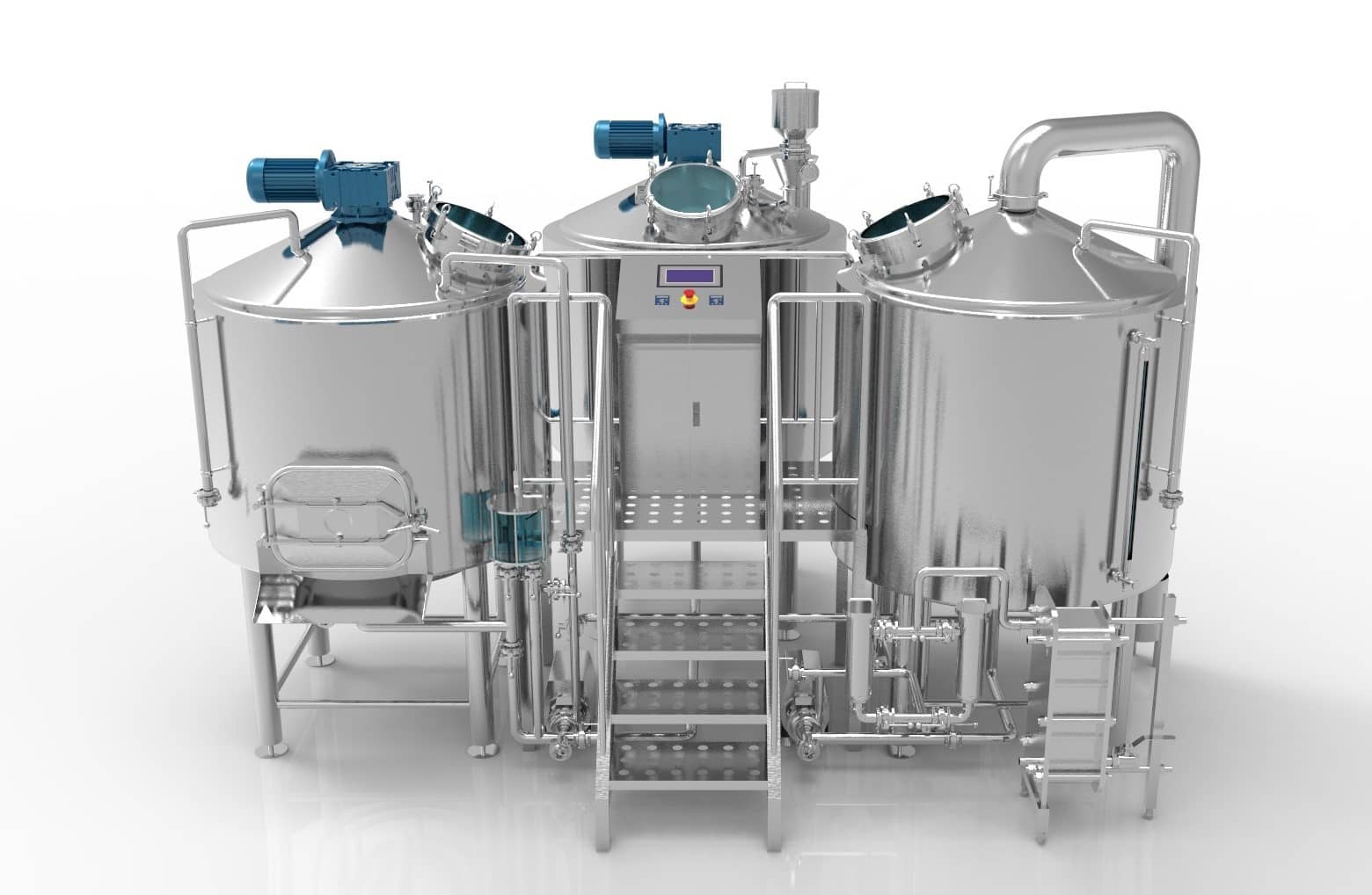

A micro craft brewery is typically defined as producing less than 15,000 barrels of beer annually. The small-scale system is flexible and customizable for crafting top quality artisanal beers.

Types of Micro Craft Brewery System

Manual vs Automated

| |

Manual |

Automated |

| Brewing Operations |

Hands-on, labor intensive |

Semi- or fully automated using controllers and sensors |

| Equipment |

Simple, minimal functionality |

Advanced features and controls |

| Brewing Precision |

Variable batch to batch |

Consistent reproducible results |

| Labor Requirements |

High staff involvement in each batch |

Lower staff requirements per batch |

| Production Volumes |

Lower total annual batches |

Higher volumes possible |

| Capital Costs |

Lower equipment expense |

Higher expense for automation |

| Learning Curve |

Accessible for new brewers |

Steeper learning curve |

All-Grain vs Extract-Based

Homebrewers expanding into a micro craft brewery may choose between adapting their all-grain brewing process or opting for extract-based commercial systems to simplify operations.

| |

All-Grain |

Extract-Based |

| Ingredients |

Base malts mashed onsite |

Brewing extracts and specialty grains |

| Mashing Process |

Required |

Not needed |

| Brewing Control |

Greater control over wort and flavors |

Less flexibility |

| Equipment |

Full mashing and lautering system |

Simplified brewhouse |

| Time Requirements |

Longer brew day |

Faster process |

| Ingredient Costs |

Lower |

Higher costs for extracts |

| Final Product |

All-grain purists prefer flavor |

Some perceive as lower quality |

Electric vs Gas-Fired

The heating system is a key equipment choice affecting performance, efficiency, safety, and ambiance.

| |

Electric |

Gas |

| Heating Technology |

Embedded electric elements |

Direct gas flame or steam from boiler |

| Control and Precision |

Excellent temperature control |

Temperature fluctuations can occur |

| Efficiency |

70-80% efficient |

Up to 95% thermal efficiency |

| Installation |

Typically simpler connections |

Gas lines, venting required |

| Operating Costs |

Lower energy costs in some regions |

Varies by gas prices |

| Brewery Atmosphere |

Cleaner |

Adds humidity; flames impact aesthetics |

| Safety Considerations |

Avoid electric around water |

Careful gas leak monitoring needed |

| Maintenance |

Low requirements |

Annual inspection recommended |

Micro Craft Brewery System Applications

Serving Fresh vs Packaged Product

| |

Draft/On Premise |

Packaged |

| Serving Method |

Draft lines straight to taps |

Bottles, cans, kegs for wholesale |

| Storage Needs |

Serving tanks only |

Full packaging line and inventory storage |

| Service Model |

Taproom sales |

Distribution model |

| Production Scale |

Match serving capacity |

Higher volumes, retail partnerships |

| Revenue Streams |

Higher margins on glass pints |

Lower per unit packaged margins |

| Customer Interaction |

Creates onsite brewery experience |

Wider audience through retail locations |

| Regulatory Requirements |

Brewpub license |

Packaging/labeling compliance |

The choice impacts layout, equipment, operations, and the overall business model. Many successful micro craft breweries offer both draft beer in an inviting taproom as well as broader distribution of packaged product.

Supplementary Spaces

| Usage |

Details |

| Taproom/Restaurant |

Space for patrons to sample beers. May require kitchen equipment subject to county health department regulations |

| Beer Garden / Patio |

Outdoor space to enjoy craft beers. Could include portable draft lines, tents, heat lamps |

| Offices and Storage Areas |

Administrative work and inventory areas as needed |

| Barrel-Aging Rooms |

Controlled climate rooms for wood-aging beers |

| Lab for Testing and Trials |

QC and experimental small batch brewing |

Configure auxiliary usage zones to support main production areas. Consider future potential to host private events or expand seating capacity.

Key Criteria for Choosing a Micro Craft Brewhouse Supplier

| Consideration |

Guidelines |

| Relevant Experience |

Look for hundreds of successful previous micro craft installations |

| Product Offerings |

Wide range meets needs from manual to fully automated |

| Customization |

Ability to get custom vessels and modify standard packages |

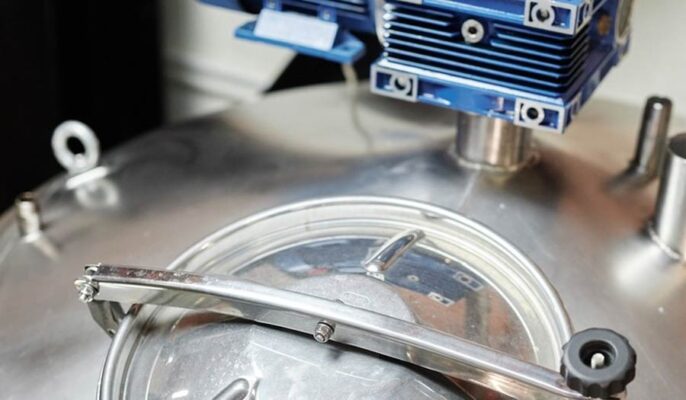

| Manufacturing Quality |

All stainless steel hand-welded vessels and parts; reputation for reliability |

| Dimensions |

Size and height fits floorplan; measure doorways and aisles |

| Lead Times |

Ready sooner than entirely custom fabricated systems |

| Service Capability |

Responsive support team handles questions and issues |

| Pricing Packages |

Compare proposals across needed equipment and features |

| Payment Terms |

Flexible installments plans help secure financing |

Top Questions to Ask Prospective Brewery Vendors

- How long have you specialized in micro craft sized brewhouses?

- Can you share contacts of micro breweries using your equipment I could call?

- Where are your manufacturing and assembly facilities located?

- Do you offer lease-to-own payment plans or financing assistance?

- Is shipping, delivery, and installation included in pricing?

- How soon could my system be operational from order date?

- Who handles warranty repairs and technical support?

- Can you help customize equipment configuration to fit my space?

Have candid conversations to determine the best fit based on needs, pricing, and service approach. Tour existing installations to inspect build quality if possible.

Comparison of Micro Craft vs Macro Brewery Systems

Micro craft breweries face distinct opportunities and challenges compared to large brewers.

Micro Craft vs Macro Breweries

| |

Micro |

Macro |

| Annual Production Volume |

< 15,000 barrels |

Over 100,000 barrels |

| Batch Size |

5-30 BBL typical |

Hundreds of BBL per batch |

| Brewing Approach |

Traditional recipes; small batches |

Focused on mass production volumes |

| Product Variety |

Constant innovation; seasonal offerings |

Flagship brands; limited specialty options |

| Ingredients |

Specialty malts, hops, yeasts |

Commodity adjuncts like corn, rice |

| Business Model |

Local taproom sales; limited distribution |

National distribution networks |

| Pricing Range |

$4.50-$10 per pint |

Under $1 per bottle at retail |

| Ownership Structure |

Often owner operated |

Corporate shareholders |

The scale requires tailored strategies to ingredients, operations, marketing, and financing. As they grow, micro craft breweries make transitions towards more automation. But retaining quality, creativity, and connections with local community remain imperatives.

Advantages and Limitations of Micro Craft Brewing

The intimate micro brewery scale enables artisanal approaches but also comes with financial and operational challenges.

Benefits and Opportunities with Micro Craft Breweries

- Freedom for brewers to experiment with recipes and ingredients

- Focus on flavor, aroma, and appearance

- Engage customers with speciality offerings and seasonal varieties

- Build loyal local following and brand identity

- Charge premium price points for perceived quality

- Lower startup capital investment requirements

- Owner operated maintains flexibility and control

- Capability to grow production incrementally avoids large debt

Potential Weaknesses and Risks Facing Small Breweries

- Consistency batch to batch can be challenging

- Floorspace limitations may constrain growth

- Stainless equipment has high upfront costs

- Securing bank loans difficult without proven financials

- Must price competitively as market saturates

- Expensive Federal and State licensing fees

- Staffing challenges finding qualified brewers

- Distribution without discounts tough for retailers

- High failure rate as fads change in craft beer

The list of considerations highlights how micro craft brewing offers great rewards but requires thorough planning. Learn from other successful breweries while crafting an identity around unique beers.

Frequently Asked Questions

What size brewery production is considered “micro craft”?

The Brewers Association defines micro craft breweries as producing under 15,000 barrels per year. That equates to brewing no more than 450,000 US gallons annually.

How much space do I need for a micro sized brewhouse?

Plan for at least 1,500-3,000 sq ft for a small 3-7 BBL micro brewery. This includes the brewhouse plus fermentation room, cold storage, packaging area, ingredients, lab, and offices. More space allows more comfortable production volumes and future growth capacity.

What are important utilities I need to operate brewery equipment?

Key utilities are electricity, water, drainage, ventilation, refrigeration, gas lines for any direct-fired kettles, and steam if applicable. Ensure adequate connection sizes, pressure, drainage slope, and phased electrical distribution.

Is buying used brewery equipment a good idea?

Used equipment saves substantially on upfront capital costs. But results vary greatly depending on age, maintenance performed, upgrades needed for controls and reconditioning, and warranty support. Evaluate operational expenses over lifetime of tanks.